-

PVC RESIN DG-1000S

PVC RESIN DG-1000S -

Heng Sheng Oxalic acid

Heng Sheng Oxalic acid -

Liaoning Dongyu Natural Barium Sulfate 1250 mesh

Liaoning Dongyu Natural Barium Sulfate 1250 mesh -

XinAn Pigment Carbon Black XA3500

XinAn Pigment Carbon Black XA3500 -

Polymer water resistant coating dispersant

Polymer water resistant coating dispersant -

F1250 Factory wholesale disposable food storage box take out not easy to break plastic food container

F1250 Factory wholesale disposable food storage box take out not easy to break plastic food container -

The Industry Caco3 Calcium Carbonate Price

The Industry Caco3 Calcium Carbonate Price

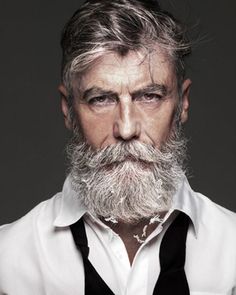

JuneSteele

I'm a seasoned industrial engineer with a keen interest in machine learning. Here to share insights on latest industry trends.