-

ZF500 American Style 500ml 750ml 10000ml Disposable Food Container Black Square PP Plastic Take Away Bento Lunch Box

ZF500 American Style 500ml 750ml 10000ml Disposable Food Container Black Square PP Plastic Take Away Bento Lunch Box -

High efficiency dispersant HT-5040

High efficiency dispersant HT-5040 -

rutile

rutile -

Dengue IgG/IgM Rapid Test Cassette

Dengue IgG/IgM Rapid Test Cassette -

China factory good quality plastic food packaging bent box 750ml disposable American plastic rectangular food box

China factory good quality plastic food packaging bent box 750ml disposable American plastic rectangular food box -

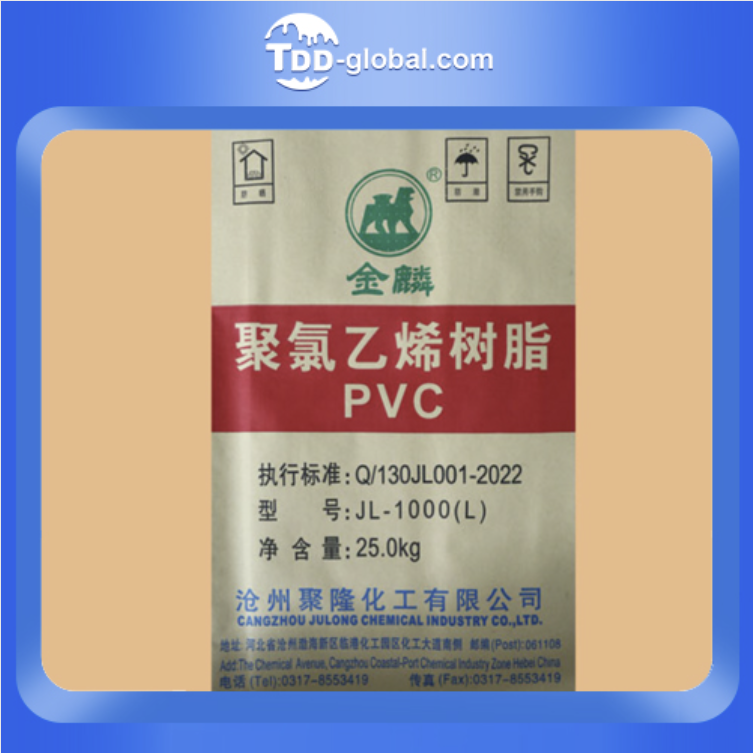

PVC JL-1000

PVC JL-1000 -

Sodium acetate anhydrous 99% White powder

Sodium acetate anhydrous 99% White powder

Q

what kind of ink is screen printing ink

I'm a seasoned industrial engineer with a keen interest in machine learning. Here to share insights on latest industry trends.

Another common name is silk screening ink; it is a special type of ink that is designed solely for the screen printing process, which basically involves the transfer of ink to the substrates (usually fabric, paper, or plastic) through a fine mesh screen. Screen printing inks can be distinguished into a few broad types based on their composition and the substrate for which they are intended: plastisol inks are mainly used for textile printing, famous for their flexible and durable nature; water-based inks, best known for their environmentally friendly features and bright colors; UV-cured inks are often selected for speedy drying and are applicable on non-porous surfaces like plastics and metals. Each type has unique properties like opacity, viscosity, and curing methods that can change the quality of the print as well as the choice of substrate. For example, plastisol inks cure at relatively low temperatures, while UV inks must be exposed to ultraviolet light. The choice of ink depends on considerations such as the substrate material to be printed, finish requirement, and environmental aspects.

You May Like

A silvery. lustrous transition metal with low density and high strength. titanium takes its name from the Greek Titans who are known for their superhuman strength.

Polypropylene is used extensively due to its unique blend of properties that make it ideal for a wide range of applications. As a type of plastic, it is remarkably lightweight yet exceedingly tough, making it suitable for items that require durability without added weight. Its resistance to many chemical solvents, bases, and acids contributes to its versatility in chemical containers and medical equipment. Polypropylene is also known for its high melting point, making it suitable for microwaveable food containers and dishwasher-safe items. Additionally, it does not absorb water, which is beneficial for outdoor and marine applications. Its recyclability further enhances its appeal as an environmentally friendlier option compared to other plastics.

Attaching PVC to cast iron pipe involves a few steps, ensuring a leak-proof connection. First, clean the end of the cast iron pipe; debris from cutting or corrosion should be removed. Use a no-hub coupling, which is specifically designed for this purpose. These couplings consist of a rubber sleeve and a stainless steel shield equipped with clamps. Slide the coupling over the end of the PVC pipe, then insert the end of the PVC pipe into the cast iron pipe. Slide the coupling so it spans the joint between the two pipes, ensuring an even distribution. Tighten the clamps on the coupling securely with a torque wrench, following manufacturer recommendations for torque settings. This creates a solid, leak-resistant seal between PVC and cast iron pipe, suitable for both drainage and vent applications in residential and commercial plumbing.

You May Like

Q&A

- •do molded polypropylene dock panels get hot in the sun

- •how to make a pvc pipe clothes rack

- •what is macrame yarn

- •how is pvc formed

- •titanium dioxide side effects

Popular Information

- •LANXESS offers even more sustainable plasticizer Mesamoll

- •NTPC REL inks MoU with GACL for green hydrogen

- •China PVC Spot Market Prices rose in August

- •The Flake Caustic Soda Prices Were Consolidating at High Levels This Week (September 4-8)

- •Malaysia’s Petronas, Singapore’s GIC and Greenko form a $2 billion green ammonia venture