YYDD (Qingdao) Technology Co., Ltd.

Retailer

CN Supplier

3 YRS

Main Products:

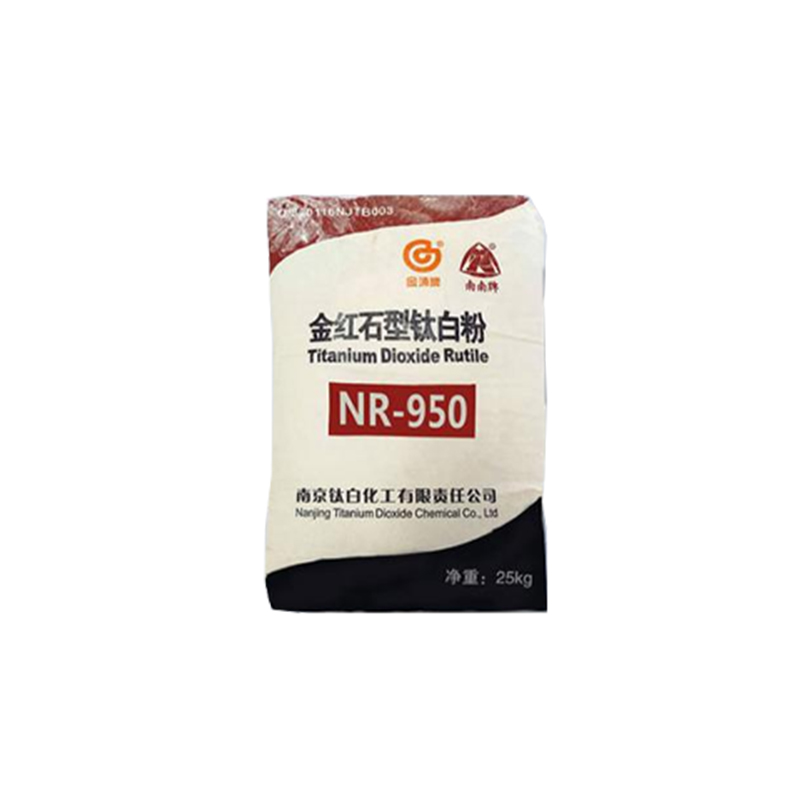

Titanium dioxide, pigments, fillers, alcohols

Established:

2022-01-26

Company Size:

10000

Beijing TDD E-commerce Co., Ltd

Online Store

CN Supplier

11 YRS

Main Products:

Titanium dioxide, pigments, fillers, alcohols

Established:

2014-12-18

Company Size:

2000