Q

are polysaccharides and polymers related

I'm a seasoned industrial engineer with a keen interest in machine learning. Here to share insights on latest industry trends.

I'm a seasoned industrial engineer with a keen interest in machine learning. Here to share insights on latest industry trends.

You May Like

Yes, we do excrete nonessential amino acids, but the process isn't as direct as excreting them in their original form. Amino acids, whether essential (cannot be synthesized by the body and must be obtained from diet) or nonessential (can be made by the body), play critical roles in various metabolic processes. When there's an excess of amino acids, the body uses what it needs, and the surplus undergoes a transformation in the liver where the amino group (-NH2) is removed in a process called deamination. This process converts the excess amino acids into urea, which the body can safely excrete through the urine. Additionally, some amino acids are directly used for energy, converted into glucose or fats, rather than being stored or excreted. Therefore, the excretion of nonessential amino acids is more about managing nitrogen balance and removing excess nitrogen from the body in a safe form.

Temporary emulsions are mixtures of two immiscible liquids (like oil and water) that eventually separate after a period of time or upon minimal disturbance. A common example is a simple vinaigrette. They require shaking or stirring before use to temporarily combine the liquids. Permanent emulsions, on the other hand, are stable mixtures that do not separate over time due to the presence of an emulsifying agent that stabilizes the mixture. Mayonnaise is a classic example of a permanent emulsion, where egg yolk acts as the emulsifier to permanently combine oil and vinegar or lemon juice. The key difference lies in the presence of an emulsifier and the stability of the emulsion. While temporary emulsions are simple mixtures that separate easily and require agitation to remix, permanent emulsions are complex and stable, owing to the emulsifiers that keep the immiscible liquids mixed together indefinitely.

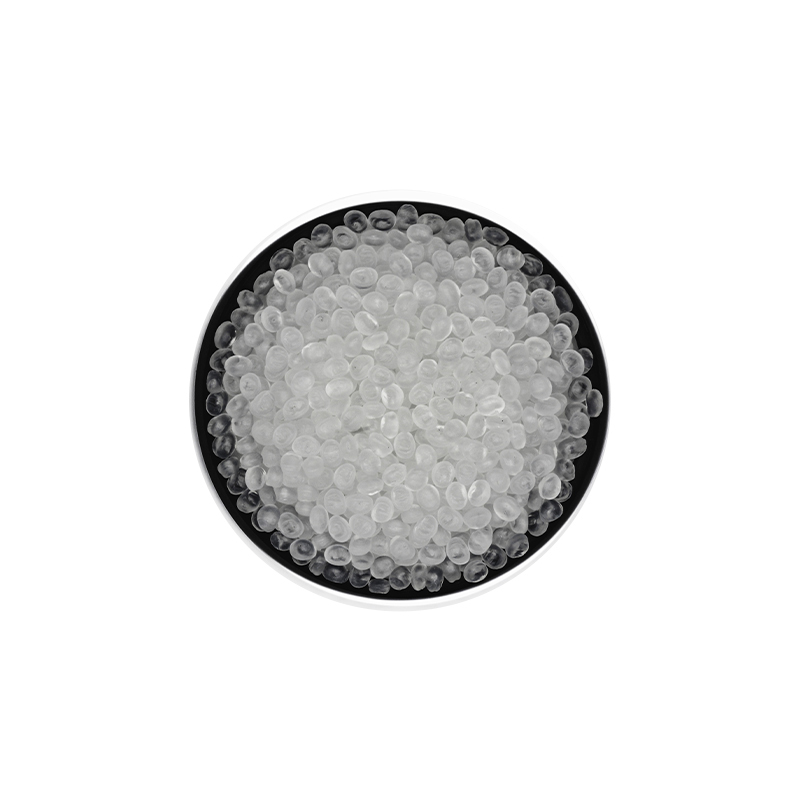

Long Chain Branched Polypropylene (LCB PP) involves the introduction of branching points within the polymer structure, creating a network that significantly impacts its mechanical and rheological properties. The actual length of these branches can vary significantly depending on the synthesis method and the degree of branching desired. However, typical molecular weight measurements, essential for understanding the length, can range widely from several thousand to over a million g/mol for the entire polymer. In practice, the specific length of the branches themselves is often not directly measured but inferred from changes in properties such as melt strength, flow behavior, and impact resistance. Techniques such as gel permeation chromatography (GPC) and rheological measurements are commonly used to characterize the branching structure indirectly. By adjusting the synthesis process, including the use of specific catalysts and polymerization conditions, manufacturers can tailor the branch length and density to achieve desired material characteristics for applications like film blowing, injection molding, and extrusion.

You May Like

Q&A

- •how long does emulsion take to dry screen printing

- •is moonstone a zircon

- •how to dye white vans

- •why are amino acids called amino acids course hero

- •how to create a mold for resin

Popular Information