-

Titanium Dioxide NTR-750

Titanium Dioxide NTR-750 -

Ultrafine nanometer barium sulfate with high oil absorption and high whiteness 8000 mesh

Ultrafine nanometer barium sulfate with high oil absorption and high whiteness 8000 mesh -

High grade new design take away food packaging lunch box cornstarch 500ml rectangle food container

High grade new design take away food packaging lunch box cornstarch 500ml rectangle food container -

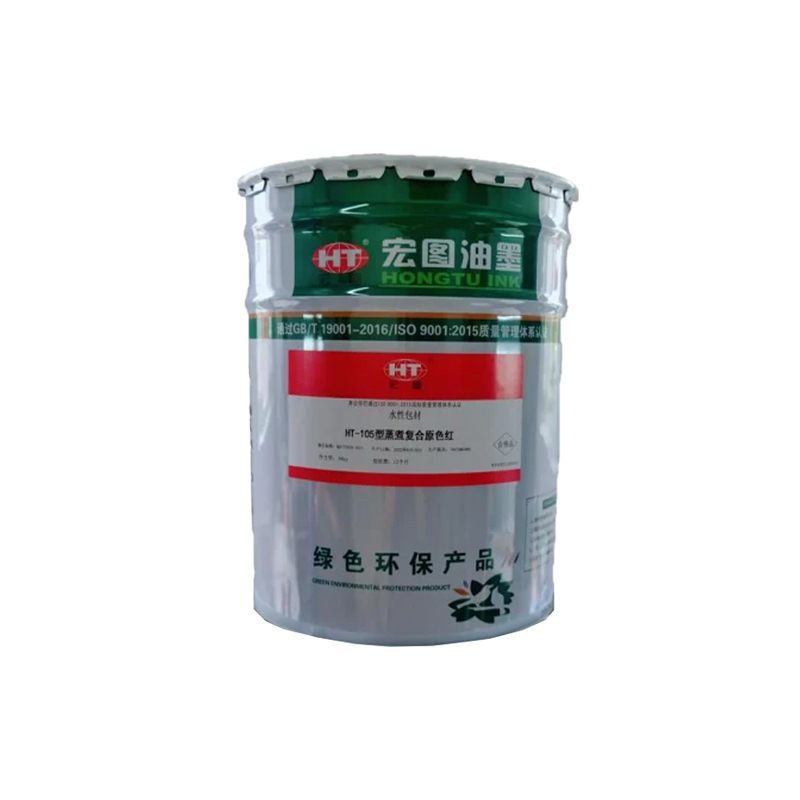

Original Red Hongtu Brand HT-105 Environmental Friendly Regular Compound Printing Ink

Original Red Hongtu Brand HT-105 Environmental Friendly Regular Compound Printing Ink -

High Purity&Whiteness Superfine Barium Sulfate 3A

High Purity&Whiteness Superfine Barium Sulfate 3A -

Light calcium carbonate YX-501

Light calcium carbonate YX-501 -

2 Compartment rectangular take off lunch box with lid disposable plastic togo container with clear lid

2 Compartment rectangular take off lunch box with lid disposable plastic togo container with clear lid

Q

must have pvc tools

I'm a seasoned industrial engineer with a keen interest in machine learning. Here to share insights on latest industry trends.

I'm a seasoned industrial engineer with a keen interest in machine learning. Here to share insights on latest industry trends.

You May Like

The 2005 Chevy Equinox is designed to use SAE 5W-30 engine oil, which is suitable for its engine requirements across a variety of temperatures, ensuring optimal performance and protection. It is crucial to use this specific grade of oil as it meets the specifications set by Chevrolet for the best lubrication and efficiency of the engine. The viscosity grade 5W-30 is recommended for its balance of flow at start-up temperatures and thickness at normal operating temperatures. Always refer to the vehicle's owner's manual for any specific recommendations or if your vehicle operates under exceptional conditions. Additionally, it might be beneficial to look for oils that meet or exceed the American Petroleum Institute (API) certification standards for added assurance of quality.

Yes, you can apply emulsion paint on top of gloss, but it requires proper preparation to ensure good adhesion. Glossy surfaces are typically smooth and non-porous, making it difficult for water-based emulsions to bond effectively. To combat this, you should sand the gloss surface to create a rougher texture which allows the emulsion to grip. Use a fine to medium grit sandpaper and gently scuff the surface, then clean it to remove any dust. Applying a suitable primer after sanding and before painting can also improve adhesion and the overall finish. It’s important to note, however, that the end result may not be as durable as applying emulsion on a more suitable matte or undercoated surface. Patch testing in an inconspicuous area is recommended to gauge results.

The stirring speed affects the viscosity of water-in-oil emulsions due to the shear forces and energy input during the mixing process. As stirring speed increases, the dispersed water droplets within the oil phase are broken down into smaller sizes due to the higher shear forces exerted. This results in a more uniform and stable emulsion with a higher surface area to volume ratio of the dispersed phase. The smaller droplet size leads to an increase in the resistance against flow, thereby increasing the viscosity of the emulsion. Additionally, the high-energy input can induce the formation of more interconnected networks between the dispersed droplets and the surrounding oil, further enhancing the viscous behavior. However, it's important to note that beyond a certain stirring speed, the viscosity might not increase significantly due to the balance between droplet breakup and coalescence rates. Understanding the optimal stirring speed is essential for achieving the desired viscosity in industrial applications where specific rheological properties are required.

You May Like

Q&A

- •does the clover mini need ink

- •what is pvd coating on a knife

- •how to remove pvc cleaner stains

- •life cycle assessment of polypropylene

- •how to epoxy a wet slab

Popular Information