Q

what color is zircon

I'm a seasoned industrial engineer with a keen interest in machine learning. Here to share insights on latest industry trends.

I'm a seasoned industrial engineer with a keen interest in machine learning. Here to share insights on latest industry trends.

I'm a seasoned industrial engineer with a keen interest in machine learning. Here to share insights on latest industry trends.

You May Like

Making polypropylene hydrophilic involves altering its surface properties since it's inherently hydrophobic. One common method is the use of plasma treatment, where the polypropylene surface is exposed to a plasma containing oxygen or ammonia, introducing polar functional groups like hydroxyl or amine groups, which enhance water absorption. Another method is chemical modification, which involves grafting hydrophilic polymers or monomers onto the polypropylene surface. UV irradiation combined with silane coupling agents is also used to improve surface hydrophilicity. Each method has its specific applications and limitations, depending on the desired degree of hydrophilicity and the intended use of the modified polypropylene.

Boat resin, a pivotal material in marine construction, refers to a polymer (often epoxy, polyester, or vinyl ester) used to provide structural strength and resistance to water and environmental damage for boats. Epoxy resin is favored for its superior adhesion and durability, making it ideal for repairs and the construction of high-performance boats. Polyester resin, being more economical, is extensively used in the manufacture of recreational boats. Vinyl ester resin merges the economical aspect of polyester with the durability closer to epoxy, offering a middle-ground. These resins not only contribute to the vessel's rigidity but also play a crucial role in protecting the hull from water ingress, impacts, and UV damage. The choice of resin depends on the specific requirements of the boat, such as its intended use, performance needs, and budget constraints.

Bingo ink, often found in bingo daubers, is specifically designed for marking on paper cards and is generally not formulated to be washable from fabrics. Some bingo inks might be water-based, which can make them easier to wash off from skin or non-porous surfaces, but when it comes to textiles, the ink can seep in and stain. If bingo ink gets on clothing, immediate action with cold water and stain removal techniques might prevent permanent staining. However, it's best to use such products with caution on or around items where spills could cause unwanted damage. In essence, while not all bingo inks are created equal, most are not designed with washability in mind, particularly when it comes to fabrics.

You May Like

Q&A

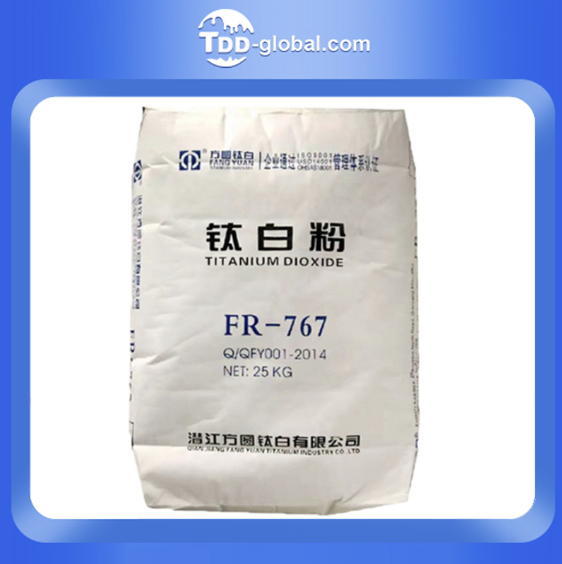

- •is titanium dioxide a natural ingredient

- •what bag material is waterproof

- •how to sythsesis peg pva resin

- •how to cut sleeves for yarn

- •how to mix emulsion paint and water

Popular Information

- •PE Market Continued to Decline Around Pessimistic Atmosphere

- •China PE Prices Weakened and Declined in October

- •Weak Demand, China PE Market Fluctuated in Narrow Range

- •KKR to give Rs 400 crore structured loan to debt-laden Sanmar Group

- •Consumer demand is very good. GST itself is creating demand: Adi Godrej