-

Citric acid anhydrous 99.8% food grade

Citric acid anhydrous 99.8% food grade -

Finest price factory directly supply lunch box plastic containers 600ml disposable plastic rectangular food box

Finest price factory directly supply lunch box plastic containers 600ml disposable plastic rectangular food box -

Food Grade Rice Protein 80% yellow powder 300/200/100Mesh

Food Grade Rice Protein 80% yellow powder 300/200/100Mesh -

Hongtu Brand HT-105 Red Environmental Friendly Universal Compound Printing Ink

Hongtu Brand HT-105 Red Environmental Friendly Universal Compound Printing Ink -

MIXTURES OF NATURAL RUBBER AND SYNTHETIC RUBBER(97.5%SMR20+2.5%SBR1502)

MIXTURES OF NATURAL RUBBER AND SYNTHETIC RUBBER(97.5%SMR20+2.5%SBR1502) -

( HCG )Pregnancy Test Strip Type

( HCG )Pregnancy Test Strip Type -

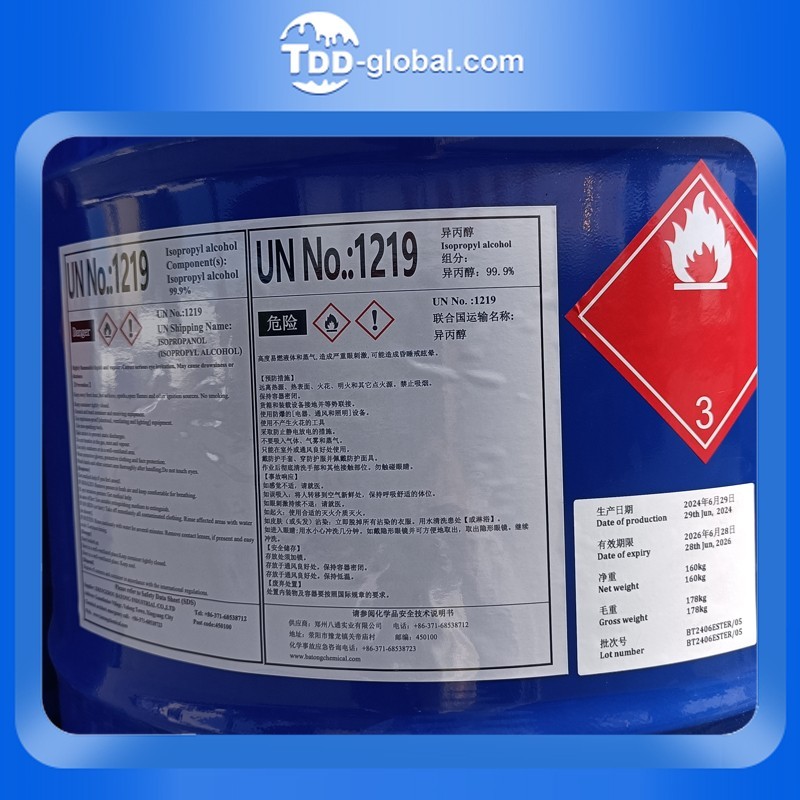

Isopropyl Alcohol

Isopropyl Alcohol

Q

what vehicles have third row seating

I'm a seasoned industrial engineer with a keen interest in machine learning. Here to share insights on latest industry trends.

Mixing different types of engine oil is generally not recommended, although it's occasionally necessary in a pinch. Engine oils have varying viscosities, additives, and specifications designed for specific engine types and operating conditions. Mixing them can dilute or alter these properties, potentially leading to reduced lubrication performance, increased wear, and engine damage over time. However, if you must mix, ensure the oils are of the same type (synthetic with synthetic, conventional with conventional) and meet the API service and viscosity requirements of your vehicle. Short-term, this shouldn't cause immediate issues, but it's preferable to use the same oil for top-ups and changes in the long run. Always consult your vehicle's manual or a professional mechanic for advice tailored to your specific situation.

A. Chrysler Pacifica. A. Dodge Caravan. A. Chrysler Town and Country. A. Chrysler Voyager.

You May Like

Despite its chemical nature. titanium is found in the earth's crust and rocks. most commonly in minerals such as titanium ore and rutile. Titanium ore is found in large quantities throughout Australia. North America. Asia and Africa. There is also a small amount of titanium used in alloys with aluminum. molybdenum. manganese. iron. and other metals.

Titanium conducts electricity. but it is not as good a conductor as copper or silver.

When selecting a router bit for polypropylene, a material known for its durability and chemical resistance, it’s crucial to choose a bit that minimizes melting and ensures a clean cut. A single-flute, carbide-tipped router bit is often a top choice due to its sharp edge and ability to maintain coolness, reducing the heat buildup that can lead to melting. Polypropylene requires precise, high-speed cutting to avoid deformation. Carbide provides the necessary hardness and longevity for cutting abrasive materials like polypropylene efficiently. Additionally, using a CNC machine with proper speed and feed rates can enhance the quality of the cut, producing smooth edges and reducing the need for post-processing. Always prioritize bits designed for plastics, as they typically feature geometries optimized for the unique challenges these materials present.

You May Like

Q&A

- •is oatmeal a fiber

- •how to make deer feeder out of pvc pipe

- •density of polypropylene plastic

- •can you use white pvc for electrical

- •how to charge polypropylene

Popular Information

- •China PE Futures Fluctuated Higher in Mid and Late August

- •This Week, the Price of Flake Caustic Soda Was Weak (January 8-12)

- •PE Prices Were Mixed This Week (April 17-21)

- •BASF doubles phenolic antioxidants capacity in Singapore

- •Caustic Soda Market Outlook: Impact of Demand, Electricity Costs, and Production Halts