Q

do electric vehicles have transmissions

Inventive Engineer: Championing creativity in engineering and disruptive technologies in the industrial sector.

South Korean automaker Kia Motors manufactures Kia vehicles.

You May Like

The drying time for PVC glue, also known as PVC cement, largely depends on the specific product used, ambient temperature, and humidity. Typically, it sets within 2-5 minutes, becoming tack-free. However, it requires 15 minutes to an hour to cure enough for handling, and a full 24 hours is recommended for the bond to achieve maximum strength. Environmental conditions play a significant role; cooler temperatures and higher humidity can prolong drying times. For optimal results, follow the manufacturer's instructions closely and ensure proper ventilation, as PVC cement emits strong fumes. Using the right amount of glue is crucial, as excessive application can extend drying times unnecessarily.

Polypropylene, a synthetic polymer widely used in textiles and fabrics due to its durability and resistance to moisture, does not inherently attract pet hair. Its smooth surface and olefin fibers make it less likely to hold onto dust, dirt, and pet hair compared to more textured materials like wool or cotton. However, static electricity can cause some pet hair adherence, but this is less of an issue with polypropylene compared to other synthetic materials. For pet owners, items made of polypropylene can be a practical choice, as they are easier to clean and maintain, reducing the hassle of pet hair accumulation.

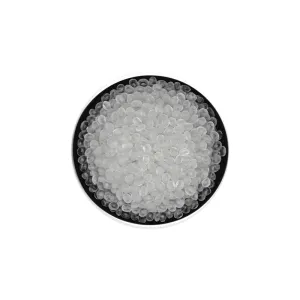

Polypropylene (PP) is a thermoplastic polymer known for its versatility and wide range of applications, from packaging materials to automotive components. The softening point of polypropylene, often referred to as its Vicat Softening Point, is a crucial thermal property indicating the temperature at which PP begins to deform under a specific load. Typically, this softening point for polypropylene ranges between 150°C and 160°C (302°F and 320°F). This temperature can vary depending on the specific type of polypropylene—whether it's homopolymer, copolymer, or a particular blend designed for enhanced qualities like impact resistance or clarity. Understanding the softening point is essential for determining polypropylene's suitability for various applications, especially those involving exposure to heat. It is also critical in processing techniques such as injection molding or extrusion, where precise temperature control is needed to achieve the desired product properties.

You May Like

Q&A

- •what family is titanium in

- •what is ilmenite smelting plant

- •is titanium malleable

- •are polypropylene pads good for acid spills

- •is fiber a vitamin

Popular Information

- •Petrochemicals will be a sector to reckon with by 2025: Experts

- •SK Geo Centric, Kolon Industries commence biodegradable PBAT production in South Korea

- •41 sectors may report 20% growth in FY 2011: CII Survey

- •Ineos partners with UPM Biofuels for renewable polymer raw materials production

- •India to impose anti-dumping duty on caustic soda from Japan, Iran, Qatar and Oman