Q

where are subaru vehicles made

I'm a seasoned industrial engineer with a keen interest in machine learning. Here to share insights on latest industry trends.

An engine can seize for several reasons, critical among them being a lack of lubrication, overheating, and internal component failure. Insufficient lubrication causes excessive friction among moving parts, leading to overheating and eventual seizure. Overheating, on another front, can result from coolant system failures or external factors, causing metal components to expand and bind. Internal component failure, such as a broken connecting rod or failed bearing, can also lead to seizure as parts become jammed inside the engine. Routine maintenance, including oil changes and cooling system checks, is essential for preventing these issues. Employing quality lubricants and ensuring proper engine cooling can significantly reduce the risk of seizure, ensuring the engine's longevity and reliable performance.

I'm a seasoned industrial engineer with a keen interest in machine learning. Here to share insights on latest industry trends.

The BlueDriver Bluetooth Pro OBDII Scan Tool has a reputation for being one of the top barcode readers for cars. Not only can it read and clear codes. but it also provides real-time data and various special functions. Compatible with both iOS and Android. this device works with a diverse selection of vehicles. Additionally. the accompanying app offers a database full of commonly asked questions and remedies. Before making a purchase. be sure to verify compatibility with your specific vehicle model. as is recommended for any similar products.

You May Like

Rev. William Gregor. an English clergyman and amateur geologist. discovered titanium in 1791.

As with all metals. in some cases scratches may occur when they come into contact with materials harder than they are. such as diamonds or abrasives.

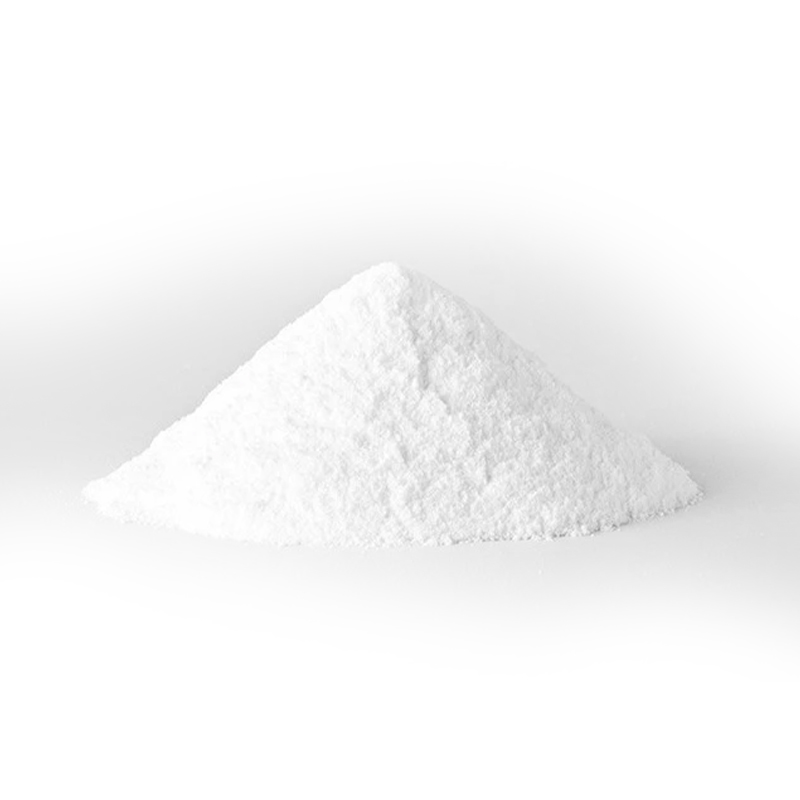

Titanium dioxide. a naturally occurring white pigment. is widely utilized in a diverse range of products. Due to its ability to block UV rays. it is a common ingredient in sunscreens. Additionally. it is sought after for its whitening properties and can be found in toothpastes. paints. and various foods. In the food industry. it may go by the label E171 and is often added to enhance the appearance of pastries and candies. However. concerns about its potential health risks have sparked controversy surrounding its use in food products. In paints. it serves to improve durability and reflectivity. This versatile substance can also be found in plastics. ceramics. and cosmetics.

You May Like

Q&A

- •how flexible is polypropylene air hoses

- •is titanium ferromagnetic

- •can i glue pvc to abs

- •pvc pipe cement drying time

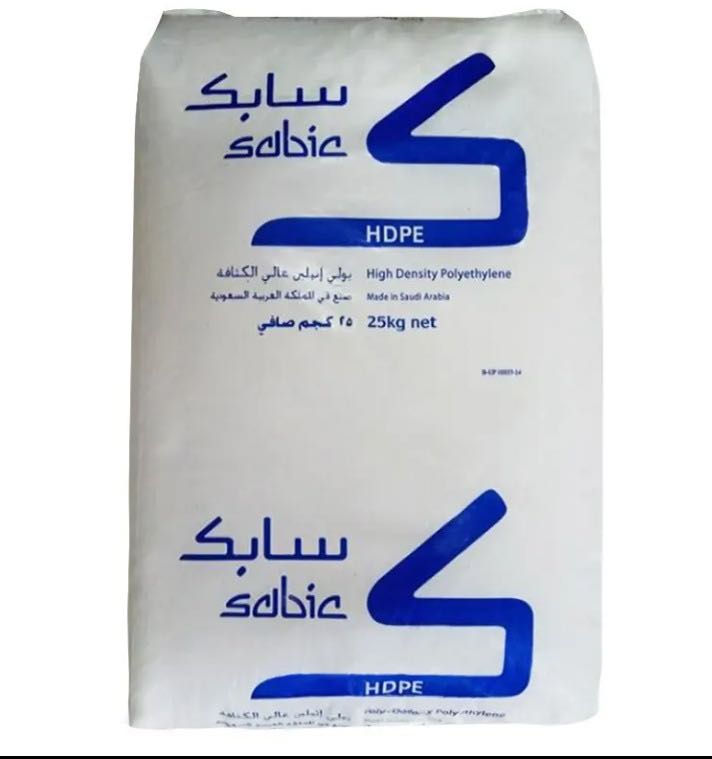

- •polypropylene granules price per kg

Popular Information

- •China PE Market Saw a slight Increase Last Week (January 1-5)

- •Egyptian government puts Indian companies in a spot

- •Grasim Q4 results: PAT rises 13% to Rs 2,617 cr; revenue rises 26% to Rs 24,399 cr

- •The Price of Flake Caustic Soda Fell This Week (March 6-10)

- •Westlake completes acquisition of Hexion’s epoxy business