-

Anatase Titanium Dioxide SWA-100

Anatase Titanium Dioxide SWA-100 -

Indian Phthalocyanine Green for special sale

Indian Phthalocyanine Green for special sale -

Food stuff Disposable Plastic fast food box Takeoff Customize Packing Box resuable Microwave clear Food Container

Food stuff Disposable Plastic fast food box Takeoff Customize Packing Box resuable Microwave clear Food Container -

PP L5E89 Baofeng Brand

PP L5E89 Baofeng Brand -

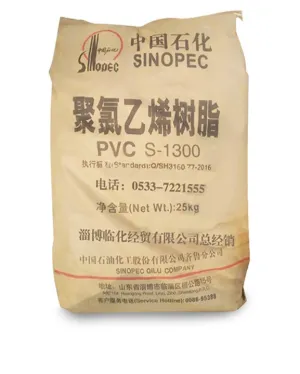

PVC Resin S-700 K55-59 Pipe Grade

PVC Resin S-700 K55-59 Pipe Grade -

Vanillin 99% white

Vanillin 99% white -

Manufacturers direct selling gift packaging boxes 3 compartment cornstarch rectangle food container

Manufacturers direct selling gift packaging boxes 3 compartment cornstarch rectangle food container

Q

what are utility vehicles

I'm a seasoned industrial engineer with a keen interest in machine learning. Here to share insights on latest industry trends.

Natural Gas Vehicles or NGVs are vehicles that are powered by natural gas instead of traditional fuel sources like gasoline or diesel. They operate using compressed natural gas (CNG) or liquefied natural gas (LNG).

They are considered a more environmentally friendly option as they emit fewer pollutants and greenhouse gases. These vehicles can include cars, trucks, buses, and even some types of ships and trains.

They are considered a more environmentally friendly option as they emit fewer pollutants and greenhouse gases. These vehicles can include cars, trucks, buses, and even some types of ships and trains.

You May Like

Titanium has low density and high strength, not only resistant to high and low temperatures, but also resistant to acid and alkali corrosion, making it an extremely high-performance metal. Since the 1950s, titanium has been widely used in the aerospace industry. In recent years, with the advancement of technology, more and more titanium has appeared in our lives.

Titanium is resistant to corrosion in sea water, aqua regia, and chlorine. This resistance is due to the formation of a thin surface layer of titanium dioxide (TiO2), which is an extremely stable ceramic. It protects the metal by resisting further attack or corrosion.

The metal burns only in an atmosphere of pure nitrogen, forming titanium nitride (TiN), which makes it unsuitable for use in atmospheres containing this gas or a high concentration of oxygen.

Titanium can be alloyed with many elements like iron, aluminium, vanadium, molybdenum to produce strong lightweight alloys for various uses such as aerospace (jet engines, missiles, and spacecraft), military, industrial, automotive, agri-food, medical prostheses, orthopedic implants, dental instruments and surgical equipment, among others.

The two most useful properties of the metal are corrosion resistance and strength-to-density ratio, the highest of any metallic element.

Even though it is quite reactive, titanium can be found pure in nature, generally as sands, or associated with other minerals, the primary ores being rutile (TiO2) and ilmenite (FeTiO3).

Titanium is resistant to corrosion in sea water, aqua regia, and chlorine. This resistance is due to the formation of a thin surface layer of titanium dioxide (TiO2), which is an extremely stable ceramic. It protects the metal by resisting further attack or corrosion.

The metal burns only in an atmosphere of pure nitrogen, forming titanium nitride (TiN), which makes it unsuitable for use in atmospheres containing this gas or a high concentration of oxygen.

Titanium can be alloyed with many elements like iron, aluminium, vanadium, molybdenum to produce strong lightweight alloys for various uses such as aerospace (jet engines, missiles, and spacecraft), military, industrial, automotive, agri-food, medical prostheses, orthopedic implants, dental instruments and surgical equipment, among others.

The two most useful properties of the metal are corrosion resistance and strength-to-density ratio, the highest of any metallic element.

Even though it is quite reactive, titanium can be found pure in nature, generally as sands, or associated with other minerals, the primary ores being rutile (TiO2) and ilmenite (FeTiO3).

Using PVC primer before applying PVC cement is highly recommended to ensure a strong and lasting joint. The primer cleans and softens the PVC surface, allowing the cement to bond more effectively. While not always mandated by building codes, skipping the primer can lead to weaker joints that may fail over time, especially in pressurized systems or in critical applications. Some situations, such as repairs in a hard-to-reach area or minimal stress applications, might seem suitable for a primer-less approach, but for reliability and compliance with most plumbing standards, using primer is the best practice.

Yes, there are side reactions in polypropylene polymerization, which can affect the yield and properties of the produced polymer. One common side reaction is chain termination, which limits molecular weight. Another is chain transfer, especially to monomer, leading to branches in the polymer chain. This branching can affect the crystallinity and melting point of the polypropylene. Additionally, unsaturated end groups can form due to β-scission, influencing polymer stability. To minimize these side reactions, precise control over reaction conditions such as temperature, pressure, and catalyst concentration is vital. Advances in catalyst design, particularly with metallocene and Ziegler-Natta catalysts, have significantly reduced the impact of these side reactions, allowing for the production of more uniform and predictable polypropylene materials.

You May Like

Q&A

- •titanium metal stock price

- •how to use stud finder zircon

- •injection blow molding limitations

- •how much fiber is in an apple

- •difference between polyolefin and polypropylene

Popular Information

- •China PE Prices slightly Increased Last Week (July 17-21)

- •PVC Market Is Stable And Weak (10.21-10.25)

- •AMAI elects Ajay Virmani as President and Aditya A. Shriram, Vice President

- •China PVC Market Fluctuated and Rose in August to Warm Up the coming of Peak Season

- •Caustic Soda Prices Rose This Week (February 14-18)