Q

who makes wagoneer vehicles

I'm a seasoned industrial engineer with a keen interest in machine learning. Here to share insights on latest industry trends.

The lifespan of a rotary engine significantly depends on maintenance and driving habits. On average, a well-maintained rotary engine in a car like the Mazda RX-7 or RX-8 can last between 100,000 to 200,000 miles. Key to longevity is proper lubrication, timely oil changes, and avoiding prolonged high-RPM driving. Rotary engines are unique in design, utilizing a rotating triangular rotor instead of pistons, which can lead to more rapid wear if not correctly cared for. Ensuring the use of high-quality fuel, regular maintenance checks, and adherence to the manufacturer’s service recommendations can extend the engine's life. However, compared to traditional piston engines, rotaries might require more frequent attention to prevent common issues such as apex seal wear.

Manufacturing Marvel: Delve into the mesmerizing world of manufacturing that forms the backbone of the industry.

Slingshot vehicles are manufactured by Polaris Industries.

You May Like

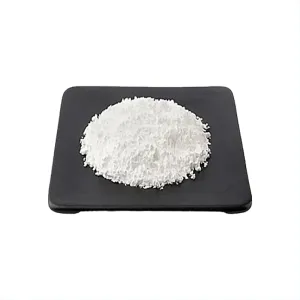

The melting point of low-density polyethylene (LDPE) film typically ranges from 105°C to 115°C. This range can vary depending on the specific formulation and processing of the LDPE. LDPE is a thermoplastic polymer made from the monomer ethylene. Its lower density is a result of its less compact molecular structure compared to high-density polyethylene (HDPE), which is due to the presence of branching in its polymer chains. This branching reduces intermolecular forces and hence lowers the melting point. LDPE's relatively low melting point contributes to its flexibility, making it ideal for applications like plastic bags, containers, and film wrap. Understanding the melting point is crucial for processing and application purposes, especially in heat-sealing and manufacturing processes where temperature control is paramount.

Deburring PVC pipe is essential for a smooth, leak-free connection. This process removes sharp or rough edges resulting from cutting, ensuring a clean fit into fittings. One common method involves using a deburring tool or sharp utility knife. Gently rotate the tool or knife at the pipe’s end, both inside and out, to shave off burrs. Alternatively, fine-grit sandpaper can be used to smooth the edges. Safety is paramount; wear protective gloves to prevent cuts. Precision in deburring ensures a secure fit, reducing the risk of leaks in your piping system.

Flame retardant polypropylene (FRPP) is a variant of polypropylene (PP) that is treated with flame retardant chemicals to enhance its resistance to ignition and combustion. This feature is crucial in applications where fire safety is paramount. FRPP is commonly used in a variety of sectors, including automotive, for parts such as battery cases and bumpers, electronics, for housing and components that must meet strict fire safety standards, and construction, for electrical conduit and other building materials that contribute to fire resistance. Additionally, it's utilized in consumer goods, such as appliances and furniture, to meet safety regulations. The flame retardant properties of FRPP are achieved without significantly compromising the material's inherent advantages, such as its light weight, chemical resistance, and ease of processing, making it an ideal choice for manufacturers seeking to enhance product safety.

You May Like

Q&A

- •how to make a soccer goal out of pvc pipe

- •is low density polyethylene toxic

- •polypropylene lifespan

- •what is a pvc payment on cash app

- •what is low pill fiber yarn

Popular Information