Delayed monsoon hits Grasim’s chemical plant at Nagda

NEW DELHI: Water scarcity in Madhya Pradesh due to delayed rains have hit the production of Aditya Birla Group’s Nagda chemical plant, where capacity utilisation currently stands at just 20 per cent.

“The water shortage is because of the poor monsoon last year,” Grasim’s Whole-Time Director Adesh Gupta told.

The $29 billion Nagda plant requires 90 lakh gallons of water a day- 80 lakh gallons for the viscose staple fibre (VSF) plant and the remaining for the chemical plant, Gupta said.

“…as the monsoon is delayed, the company’s chemical plant at Nagda is running at 20 per cent of its rated capacity fo 700 tonnes per day till the onset of monsoon,” Grasim said.

While the chemical plant stays under-utilised, the continuing scarcity of water had compelled Grasim Industries earlier this month to temporarily stop production of its VSF plant at Nagda.

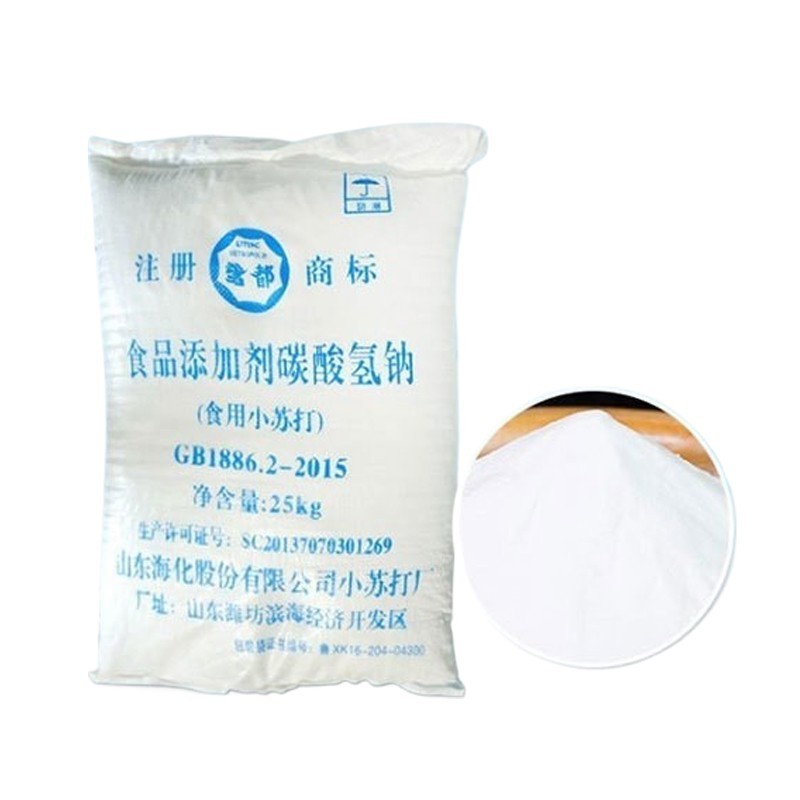

The chemical plant, a rayon-grade caustic soda manufacturing unit of Grasim Industries, was set up at Nagda in 1972, with an initial capacity of 33,000 tpa. This was subsequently enhanced to 258,000 tpa, making it India’s second largest caustic soda unit.

Rayon-grade caustic soda is a raw material used in production of viscose staple fibre (VSF), which inturn, is used in manufacturing apparels, home textiles, dress material and knitted wear applications.

Grasim had started VSF production in Nagda in 1954, which is its largest VSF producing unit. It is also the largest producer of spun-dyed specialty fibre in the world.

Besides Nagda, Grasim’s VSF plants are located at Kharach in Gujarat and Harihar in Karnataka, with a total capacity of 333,975 tpa.

Recommended Suppliers

September 23, 2024

September 23, 2024  June 3, 2024

June 3, 2024  June 3, 2024

June 3, 2024  June 17, 2024

June 17, 2024  June 18, 2024

June 18, 2024