Q

can you crystalize zircon in the lab

I'm a seasoned industrial engineer with a keen interest in machine learning. Here to share insights on latest industry trends.

I'm a seasoned industrial engineer with a keen interest in machine learning. Here to share insights on latest industry trends.

Explore the world of industrial supply chain management. Stay updated on the latest strategies, trends, and discussions in logistics and operations.

You May Like

The plant cell wall, a complex structure primarily composed of cellulose, hemicellulose, and lignin, also contains hydrophobic polymers to aid in its functions. Cutin, found mainly in the cuticle, a waxy layer external to the epidermis of leaves and other organs, is one such hydrophobic polymer. Its primary role is to minimize water loss and provide a barrier against microbial pathogens. Additionally, suberin, another hydrophobic polymer, can be found in the cell walls of cork cells and endodermal cells, where it plays a crucial role in water regulation and protection against pathogens. These polymers are essential for the plant’s ability to conserve water and protect against environmental stresses.

When comparing PVC decking to composite decking in terms of temperature, it's generally observed that PVC decks are somewhat cooler to touch under direct sunlight. Composite decking, which is made from a blend of wood fibers and plastic, tends to absorb more heat, consequently feeling warmer. The key difference lies in the materials used in their construction. Pure PVC decking doesn't contain any wood fibers, which contribute to heat retention in composite materials. However, the color of the decking plays a significant role too; lighter colors in both materials will naturally be cooler than darker shades. Although PVC might offer a cooler surface, it's important to consider other factors such as durability, aesthetic preference, and cost when making a decision between the two options.

Polypropylene (PP) is a versatile thermoplastic polymer known for its excellent chemical resistance, elasticity, and fatigue resistance. It's widely used in packaging, textiles (such as ropes, thermal underwear, and carpets), automotive components (like batteries and bumpers), and consumer goods due to its low cost and easy manufacturability. PP is favored for its ability to be easily customized through copolymerization, resulting in materials ranging from rigid to highly flexible. Additionally, PP's low density makes it a desirable choice for lightweight applications. Its resistance to various chemical solvents, bases, and acids extends its usability across many industries, including medical for manufacturing syringes and containers due to its sterility after autoclaving. Recycling and environmental impact considerations are increasingly important, with efforts to improve PP's recyclability and explore bio-based alternatives.

You May Like

Q&A

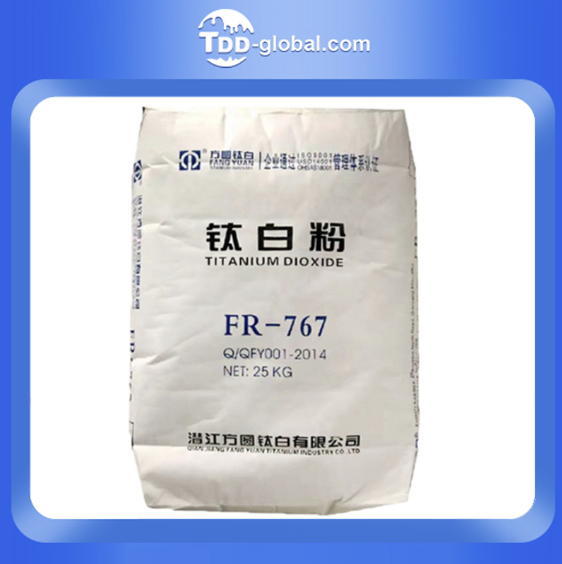

- •where can i find titanium ore

- •does linen yarn shrink

- •alkyl polyglycoside wetting agent

- •what is multifilament yarn

- •is polypropylene safe for food storage fda

Popular Information

- •Epigral Q4 FY24 QoQ PAT up 55% at Rs. 77 Cr

- •Epigral Q3 FY24 consolidated PAT up QoQ at Rs. 49.08 Cr

- •Grasim and Lubrizol to set up 1 lakh MTPA CPVC resin facility in Gujarat

- •Punjab Alkalies an exception among caustic soda makers as stock fails to make the most of rally

- •Vinyl institute has joined the Cyclyx consortium