-

Danshai Chemicals Paper Grade Talcum Powder 3000mesh

Danshai Chemicals Paper Grade Talcum Powder 3000mesh -

GA-SERIES GENERAL GRAVURE INK FOR PLASTIC LAMINATED FILM

GA-SERIES GENERAL GRAVURE INK FOR PLASTIC LAMINATED FILM -

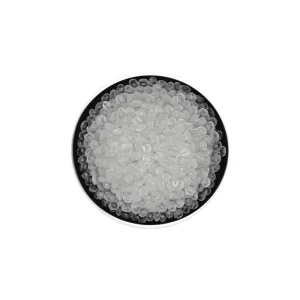

Factory Price Virgin PP Raw Material

Factory Price Virgin PP Raw Material -

TAISOX high density polyethylene particles

TAISOX high density polyethylene particles -

Cellulose Ether 4017

Cellulose Ether 4017 -

XH-3G-1 Cornstarch 3 compartment rectangle food container takeout lunch box

XH-3G-1 Cornstarch 3 compartment rectangle food container takeout lunch box -

MY450 disposable plastic 450ml food container

MY450 disposable plastic 450ml food container

Q

how many vehicles does jay leno own

I'm a seasoned industrial engineer with a keen interest in machine learning. Here to share insights on latest industry trends.

Engine mounts are critical components in vehicles, serving primarily to secure the engine to the vehicle's frame or chassis, while also dampening vibration and noise produced during engine operation. These mounts are typically made from a combination of rubber and metal, allowing them to effectively absorb and isolate vibrations, thus enhancing the driving experience by reducing the amount of noise and roughness felt inside the cabin. Over time, engine mounts can wear out or break due to the constant stress and vibration, leading to increased engine movement, noise, and potentially damaging components. It is crucial to maintain and inspect these mounts regularly to ensure the engine remains properly positioned and to preserve the overall health of the vehicle. Replacing worn or broken mounts is essential for vehicle safety and comfort, making it an important aspect of vehicle maintenance.

#6 - Industry Bold: All about the risks and rewards of the rapidly evolving industrial landscape.

In 2020. Ford will sell approximately 4.18 million vehicles worldwide. However. these numbers can fluctuate depending on a variety of factors. including economic conditions and market demand.

You May Like

With its high brightness and refractive index. titanium dioxide is a sought-after ingredient in many products. It can maintain the white. bright. and UV-resistant qualities of paints. lacquers. and plastics. Additionally. it acts as a colorant in food and cosmetics. enhancing the whiteness of processed foods. toothpaste. and sunscreen. Additionally. it serves as a photocatalyst to transform sunlight into chemical energy and has applications in reducing pollution in wastewater treatment plants. However. concerns regarding its safety when ingested or inhaled continue to arise.

Radiators are typically not made from polypropylene or polyethylene due to these plastics' thermal characteristics. These materials do not have sufficient heat resistance and conductivity for the high temperatures involved in a radiator's operation. Radiators must efficiently transfer heat from the hot coolant inside to the air outside. Metals such as aluminum or steel are commonly used materials because they have much higher thermal conductivity and can withstand the operational conditions of radiators. Polypropylene and polyethylene are more likely to be found in components that do not require high heat resistance or conductivity, such as some automotive fluid containers or ducts.

The number 3287.

You May Like

Q&A

- •what color is polypropylene

- •how long does pvc cement need to cure

- •at what temperature does titanium melt

- •how to connect pvc to cpvc

- •what does yarn dev do

Popular Information

- •Retreat of Western investment in China: Views from within

- •India needs fourteen cracker units by 2040: Reep Hazarika, Managing Director, Brahmaputra Cracker and Polymer Ltd.

- •China PVC Spot Prices Rose Last Week (July 7-14)

- •The Price of Caustic Soda Declined in October as a Whole

- •Aditya Birla Chemicals gets shareholders’ nod for merger with Grasim Industries