Q

what are connected vehicles

I'm a seasoned industrial engineer with a keen interest in machine learning. Here to share insights on latest industry trends.

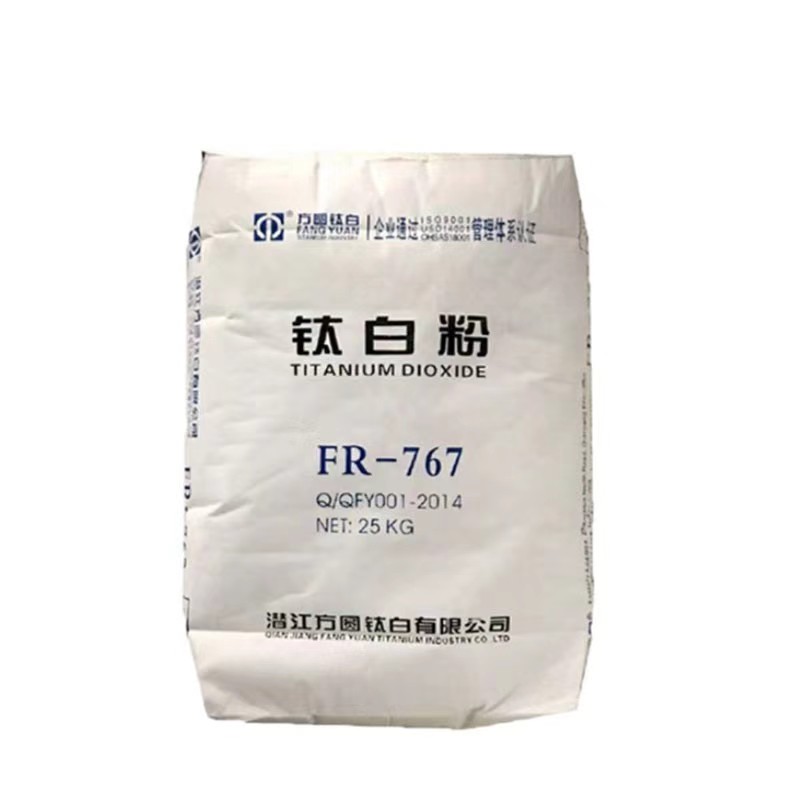

Titanium dioxide (TiO2), commonly used as a food additive (E171) for whitening and enhancing the brightness of products, faced scrutiny due to health concerns. The European Food Safety Authority (EFSA) re-evaluated its safety in 2021 and concluded that it could no longer be considered safe as a food additive, citing concerns over genotoxicity (the ability to damage DNA). Following this, the European Union decided to ban its use in food products effective from 2022. As the UK has left the EU, it does not directly follow EU regulations post-Brexit. However, the UK's Food Standards Agency (FSA) and Food Standards Scotland (FSS) initiated a review of the EFSA's assessment to consider if the UK should implement a similar ban. As of my last update, the UK had not officially banned titanium dioxide, but the situation could change pending the outcome of these reviews.

[WorldOfWork]: Examining the evolving world of industrial labor and the impacts of automation, digitalization, and artificial intelligence.

American-made vehicles refer to those cars, trucks, and SUVs that are manufactured in the United States by American-based car companies. Examples include:

1. Ford: Models include Mustang, F-150, Explorer, and Escape.

2. General Motors (Chevrolet, GMC, Cadillac): Models include Silverado, Yukon, Corvette, and Escalade.

3. Chrysler (Dodge, Jeep, Ram): Models include Charger, Grand Cherokee, and Ram trucks.

4. Tesla: All models, including Model S, Model 3, Model X, and Model Y.

Many foreign companies such as Honda, Toyota, Subaru, BMW, and Mercedes-Benz also have plants in the U.S. and make certain models here, but the parent companies are based outside of the U.S.

1. Ford: Models include Mustang, F-150, Explorer, and Escape.

2. General Motors (Chevrolet, GMC, Cadillac): Models include Silverado, Yukon, Corvette, and Escalade.

3. Chrysler (Dodge, Jeep, Ram): Models include Charger, Grand Cherokee, and Ram trucks.

4. Tesla: All models, including Model S, Model 3, Model X, and Model Y.

Many foreign companies such as Honda, Toyota, Subaru, BMW, and Mercedes-Benz also have plants in the U.S. and make certain models here, but the parent companies are based outside of the U.S.

You May Like

The cost of polypropylene per pound can fluctuate significantly due to factors such as crude oil prices, demand in various industries (like automotive and packaging), and global economic conditions. As of my last knowledge update in 2023, prices generally ranged from $0.50 to $0.80 per pound for bulk quantities in the United States. It's important to note that prices can vary based on the grade of polypropylene and the volume of the purchase. For smaller quantities or specialized grades, prices can be higher. For the most accurate and current pricing, contacting suppliers directly or checking market reports is recommended, as these figures can quickly become outdated due to market volatility.

Polypropylene (PP) inherently has some resistance to ultraviolet (UV) radiation, but it is not fully UV stable. Under prolonged exposure to sunlight, PP can degrade, leading to changes in color, loss of strength, and brittleness. This degradation is due to the polymer chain breaking down when exposed to UV light. However, the UV stability of polypropylene can be significantly improved through the addition of UV stabilizers during the manufacturing process. These stabilizers absorb or screen out UV radiation, protecting the polymer from damage. For applications that require prolonged outdoor exposure, it is essential to use UV-stabilized PP to ensure durability and longevity. In summary, while polypropylene has some natural resistance to UV light, for outdoor applications, it is crucial to use PP that has been specifically treated with UV stabilizers.

Composite materials made from polyvinyl chloride resins and various added additives and reinforcing materials are different types of an engineered material called PVC composites. This combination would improve mechanical properties, stability, and flexibility of standard PVC, which is designed for a wide range of applications. Usually, reinforcement might include wood flour, fiber glass, and other natural fibers to improve strength and reduce thermal expansion. PVC composites have several advantages over traditional materials like wood or metals; they are lightweight, moisture-, rot-, and insect-resistant, and require minimum maintenance. Other advantages range from outdoor furniture, window frames, fencing to decking. These can be further custom designed by coloring and texturing processes to imitate the beauty of wood and other materials. That said, despite these qualities, there remain those who argue that PVC, used as production and disposal processes, has a bad environmental impact; therefore, producers are trying to identify more sustainable alternatives.

You May Like

Q&A

- •density of polypropylene g cm3

- •boiling point of polypropylene

- •melting point for pvc

- •who discovered low density polyethylene

- •how to make titanium dioxide pigment

Popular Information

- •China PE Prices slightly Increased Last Week (July 17-21)

- •Wood secures FEED contract for Chandra Asri’s CAP2 petchem complex

- •Ind-Ra upgrades Chemplast Sanmar to ‘Ind A+’/Positive

- •Hydrochloric Acid Prices Surge in Europe and US Amidst Supply Chain Disruptions

- •Chemical price rules steady in thin trading