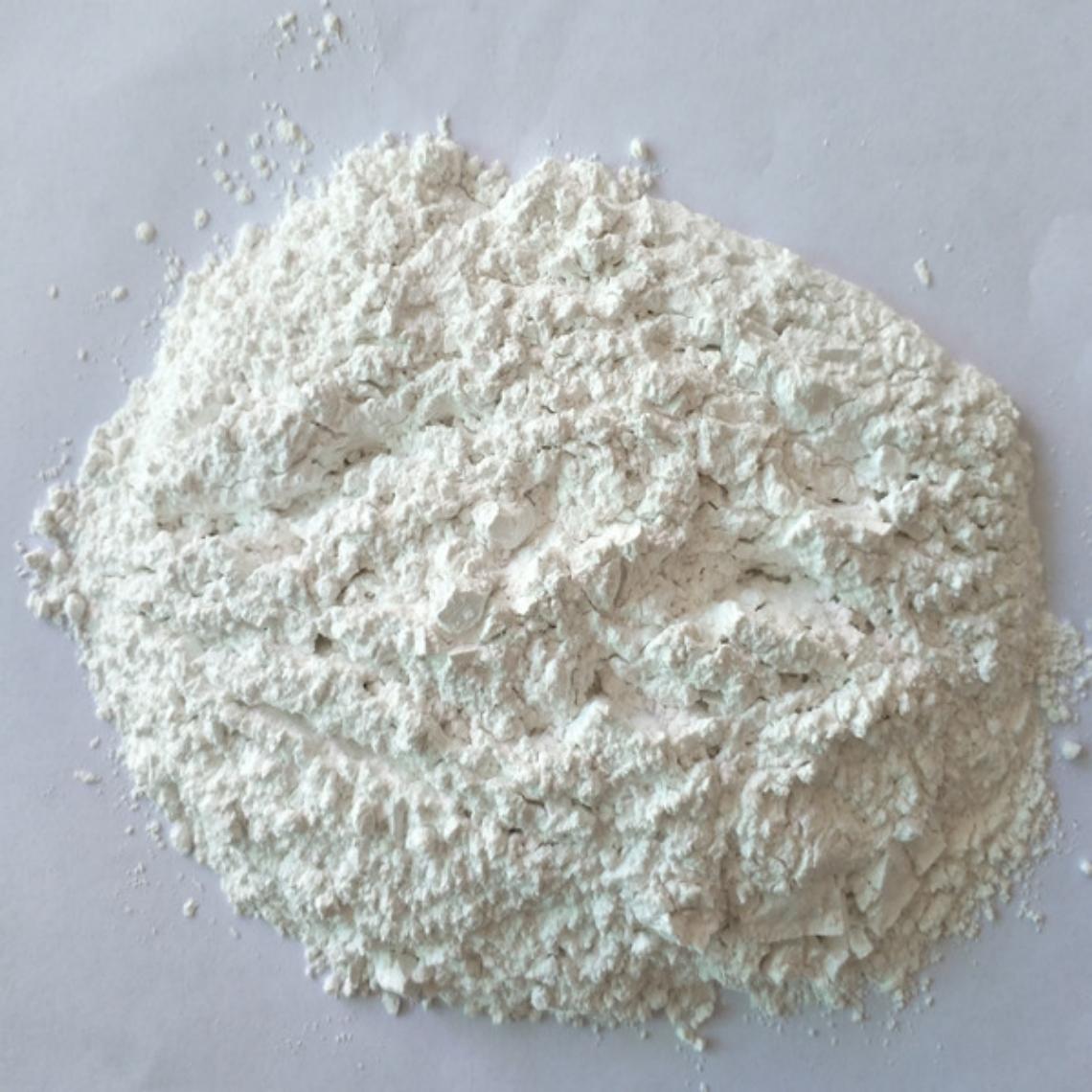

Vietnam High Whiteness Heavy 400 Mesh Calcium Carbonate Crecarb 8

| Product Model | CreCarb 8 |

| Number of mesh | 400 |

| Whiteness | 98 % Min |

| D50 | 8.0± 0.3 µm |

| D97 | 35± 2 µm |

| Application areas | plastics, coatings |

Characteristic:

1. The carbonation method is used. After the limestone is calcined at high temperature, it is first digested with water, and then screened, carbonized, surface treated, dried and crushed to obtain colloidal calcium carbonate. High standard calcium carbonate can help save expensive fibers by increasing the mineral content of printing and writing grades, thereby reducing production costs or improving production capacity; Enhance mechanical properties and improve productivity of various plastic applications.

2. Stable performance and high whiteness

CaCO3 content: 98.5% (minimum)

Whiteness: 98% (minimum)

Brightness: 96% (minimum)

3. Wide application Calcium carbonate is mainly used in papermaking (paper, cardboard and paper towel), polymers (films, plates, pipes and profiles, cables, floors, rubber, elastomers and thermoset plastics), building materials (paints, coatings, adhesives and sealants, ceramic tiles and ceramics) and life sciences (feed, personal care, agriculture and environment).

| Company Name | Beijing TDD E-commerce Co., Ltd | Country | China |

| Business Type | Online Store | Company Size | 2000 |

| Established | December 18, 2014 | ||

| Address | Building No.3, Area 6, No.188, West of South Forth Ring Rd, Beijing, China | ||

| Main Products | PVC Resin , PP , PE , Pet , Titanium Dioxide , Pigment , Car Tire | ||

| International Commercial Terms(Incoterms): | FOB, CFR, CIF, FCA | ||

| Terms of Payment: | LC, T/T, D/P | ||

| Average Lead Time: | Peak Season Lead Time: one month, Off Season Lead Time: within 15 workdays | ||

| Number of Foreign Trading Staff: | 20~40 People | ||

| Main Markets: | Southeast Asia, Africa, Mid East | ||

| Nearest Port: | Tianjin,Qingdao,Shanghai | ||

| Import & Export Mode: | Have Own Export License | ||