Advantages and disadvantages of sulfuric acid and chlorination titanium dioxide in plastics

The plastics industry is the second largest user of titanium dioxide, accounting for about 18% of the world's total titanium dioxide demand. It is the fastest-growing area of titanium dioxide application in recent years, with an average annual growth rate of 6%. More than 500 titanium dioxide brands in the world, more than 50 brands are special for plastics.

An important branch of plastics and an important application field of titanium dioxide in plastics-UPVC profiles have developed at an alarming rate in China in the past ten years, increasing at an average rate of 10%.

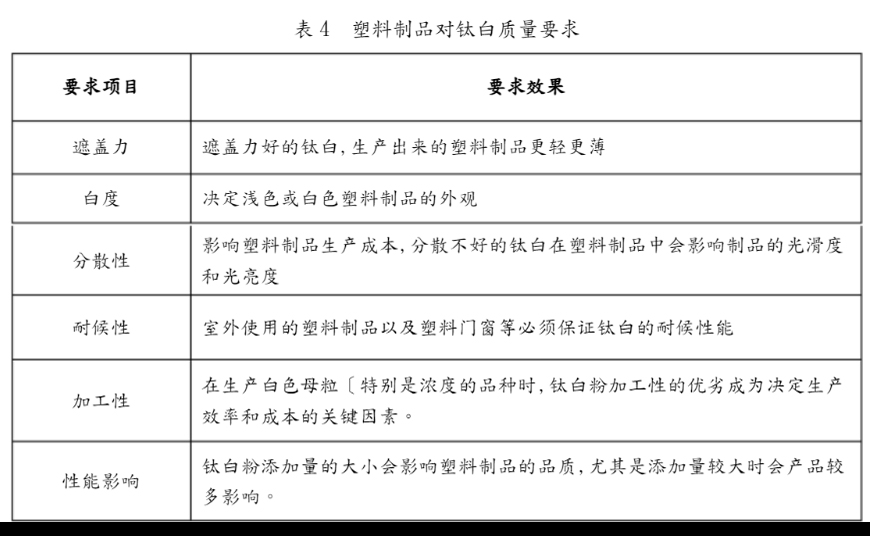

Titanium dioxide used in the production of ordinary plastics does not require weather resistance, but focuses more on the requirements of pigment performance.

For titanium dioxide for plastics, it is required to have fine particles, good dispersibility, good heat resistance and light resistance, and will not change color during heating during plastic molding and the finished product during sunlight exposure and use.

Most titanium dioxide for plastics has a relatively fine particle size. Generally, the particle size of titanium dioxide for coatings is 0.2 - 0.4μm, while the particle size of titanium dioxide for plastics is 0.15 - 0.3μm, so that blue color can be obtained. The base phase has a masking effect on most resins with yellow phase or resins that are prone to yellowing. Moreover, if titanium dioxide is used instead of lithopone, the consumption of white pigment can be reduced by 50% to 70%.

An important branch of plastics and an important application field of titanium dioxide in plastics-UPVC profiles have developed at an alarming rate in China in the past ten years, increasing at an average rate of 10%.

In 2008, the national profile output was 3.8 million tons, and the rutile TiO2 used was approximately 135,000 tons. According to the annual increase of 10% in profiles across the country, the national profile industry required about 150,000 tons of TiO2 in 2009, and in 2010 it reached 165,000 tons.

Titanium dioxide used in the production of ordinary plastics does not require weather resistance, but focuses more on the requirements of pigment performance.

For titanium dioxide for plastics, it is required to have fine particles, good dispersibility, good heat resistance and light resistance, and will not change color during heating during plastic molding and the finished product during sunlight exposure and use.

Most titanium dioxide for plastics has a relatively fine particle size. Generally, the particle size of titanium dioxide for coatings is 0.2 - 0.4μm, while the particle size of titanium dioxide for plastics is 0.15 - 0.3μm, so that blue color can be obtained. The base phase has a masking effect on most resins with yellow phase or resins that are prone to yellowing. Moreover, if titanium dioxide is used instead of lithopone, the consumption of white pigment can be reduced by 50% to 70%.

Comparison of two processes of titanium dioxide in plastic applications

It is understood that the titanium dioxide used in Chinese plastic products, especially high-end products, still mainly uses imported chlorinated titanium dioxide. Chlorinated titanium dioxide is not only superior to sulfuric acid titanium dioxide in terms of whiteness and other appearance properties, but also has unparalleled advantages in covering power, dispersibility, and processability, especially for outdoor UPVC plastic profile products and chlorinated rutile products.