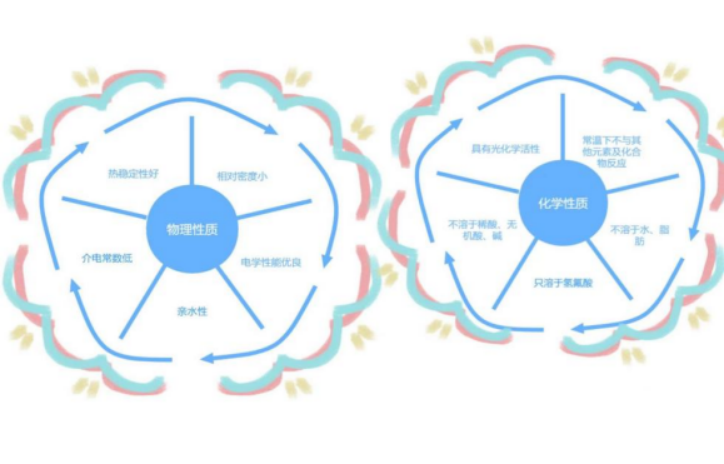

Titanium dioxide: The scientific name of titanium dioxide is titanium dioxide, and the English name is Titanium Dioxide. It is an important inorganic chemical pigment. The main component is titanium dioxide and the molecular formula is TiO2. It is insoluble in water and weak acid, and soluble in concentrated sulfuric acid. Alkali and hydrofluoric acid.

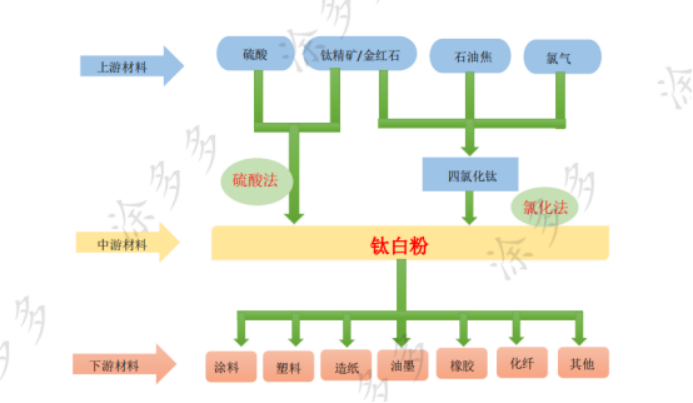

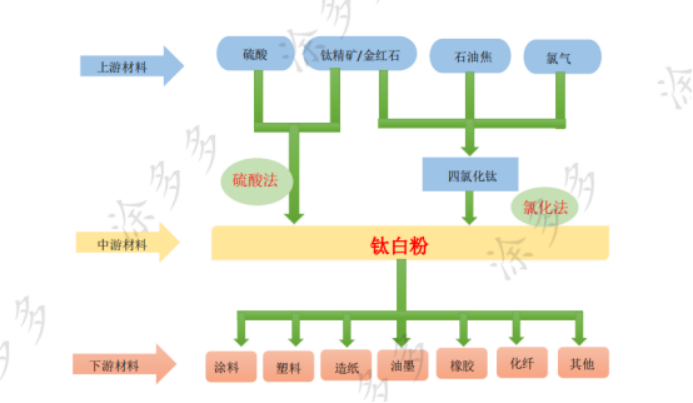

Titanium dioxide industry chain map: The upstream of the titanium dioxide industry chain are raw materials, including ilmenite, ilmenite, rutile, etc.; the middle reaches are titanium dioxide products, and the downstream is the application field of titanium dioxide. Titanium dioxide is widely used in coatings, plastics, papermaking, inks, rubber and other fields.

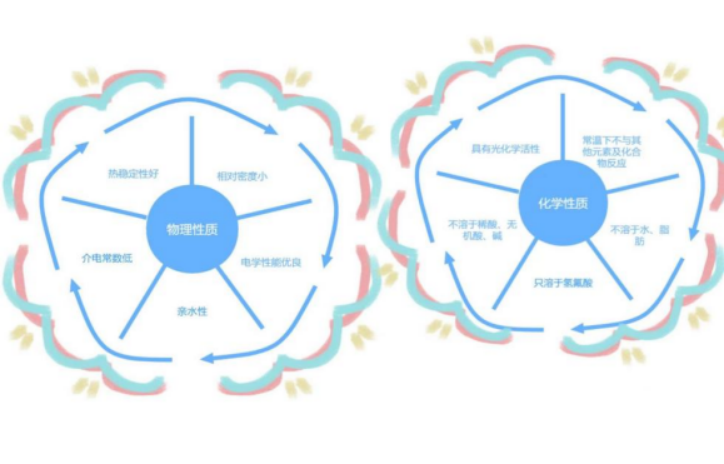

Physical and chemical properties of titanium dioxide:

Preparation method of titanium dioxide: The titanium dioxide production process mainly includes sulfuric acid production process and chlorination production process.

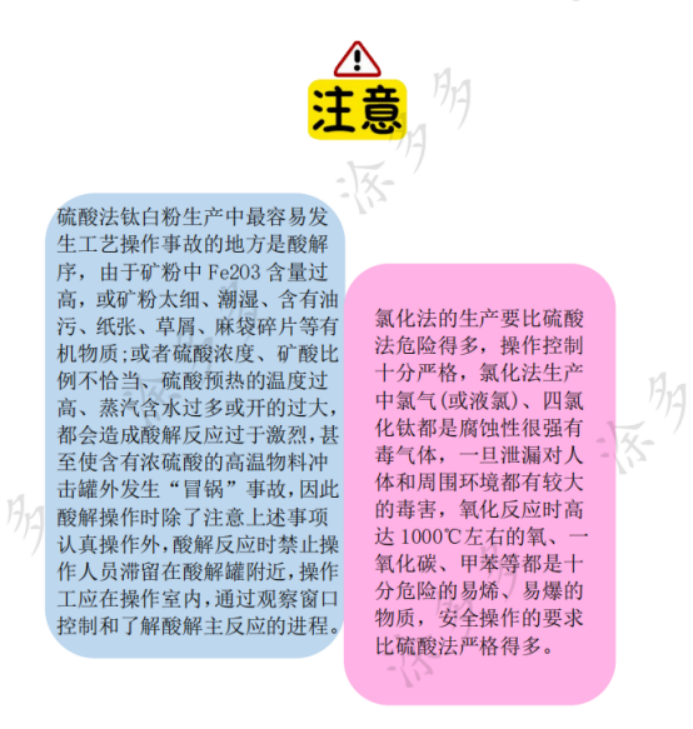

The sulfuric acid method titanium dioxide production process is to acid hydrolysis reaction between titanium iron powder and concentrated sulfuric acid to produce titanous sulfate, which is hydrolyzed to produce metatitanic acid, and then calcined and crushed to obtain titanium dioxide product. This method can produce anatase and rutile titanium dioxide.

The production process of titanium dioxide by the chlorination method is to mix rutile or high-titanium slag powder with coke and then chlorinate it at high temperature to produce titanium tetrachloride. It is oxidized at high temperature, filtered, washed, dried and crushed to obtain titanium dioxide product. The chlorination process of titanium dioxide production can only produce rutile products.

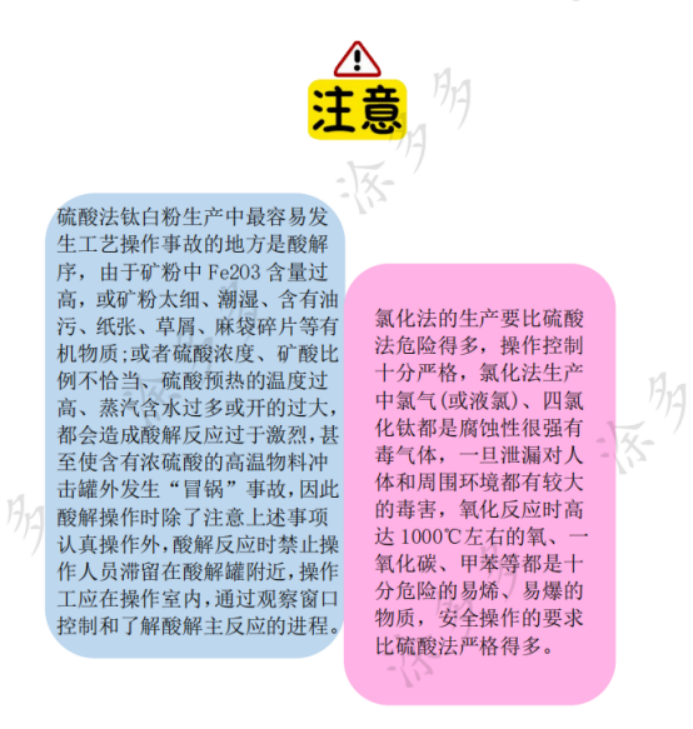

Precautions for the production of titanium dioxide: When producing titanium dioxide, most of the raw and auxiliary materials used are non-toxic, but attention should also be paid to protecting toxic substances. When using all items, protective work should be done in accordance with the requirements in the instructions for use and the requirements in the factory safety regulations. During the entire production process, protective equipment must be worn during operation.

Analysis of titanium dioxide level:

Slurry level: Titanium dioxide exists in slurry in liquid form, which is generally used for spinning, coatings, food, etc.;

Powder level: Under normal circumstances, titanium dioxide is powder when it comes out of the kiln. It is powder without slurry treatment;

Pigment grade: used for paints, paints, etc.;

Non-pigment grade: refers to those titanium dioxide for special purposes, such as electronics, batteries, optical glass, ceramics, etc.

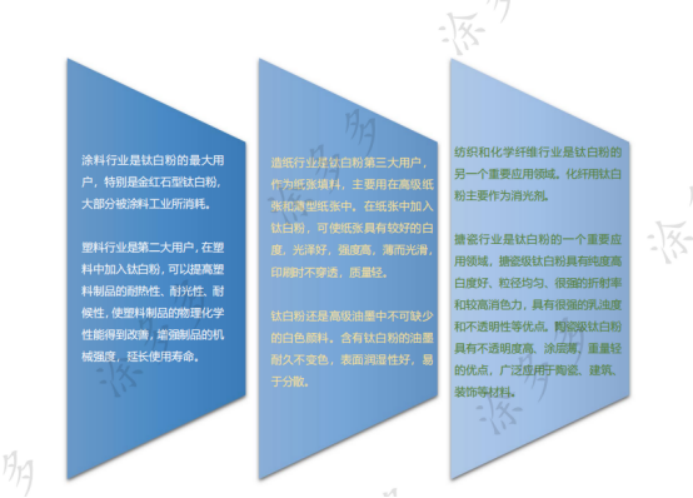

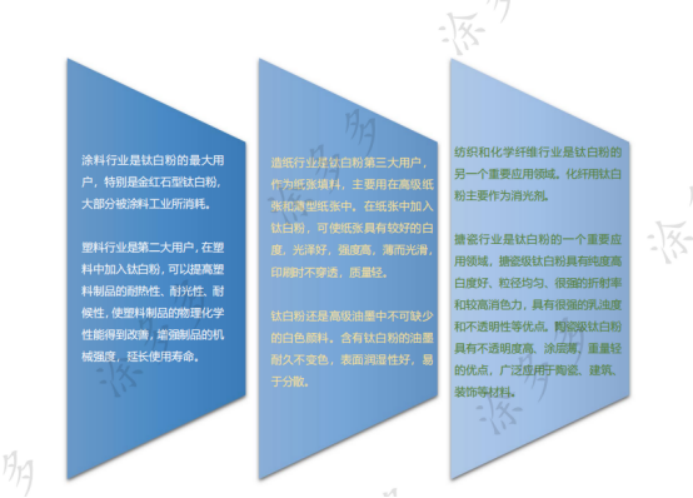

Application fields of titanium dioxide: Titanium dioxide (TiO2) is a very stable oxide that does not react with most substances under normal circumstances. Its harmlessness, best opacity, best whiteness and brightness are considered to be the best performing white pigment in the world, and its coloring power, covering power, weather resistance and heat resistance are also very good. Widely used in coatings, plastics, papermaking, printing inks, chemical fiber, rubber, cosmetics and other industries. The most important application areas are the following three major parts:

Global titanium dioxide production capacity industry situation:

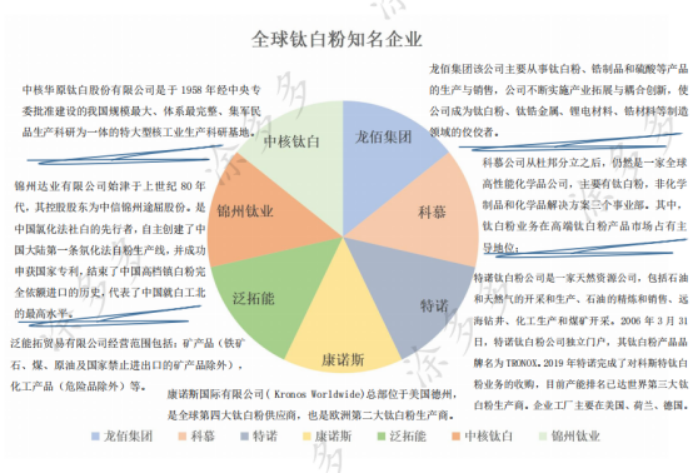

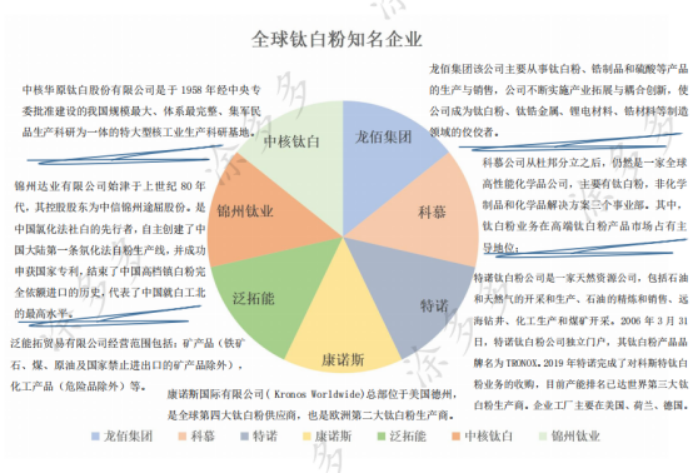

Global well-known titanium dioxide companies:

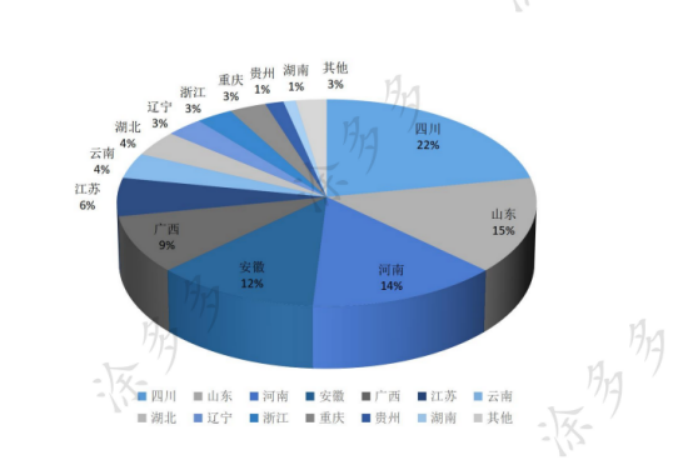

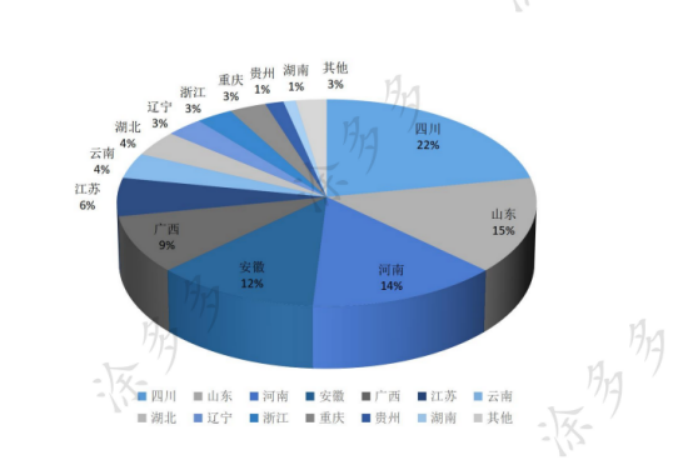

Regional production distribution of titanium dioxide in China: