AVIC Mate Additive Materials Technology (Beijing) Co., Ltd.(referred to as "AVIC Mate") was established in 2015 and is headquartered in Beijing Economic and Technological Development Zone. It is a state-owned enterprise in Beijing, a "Science and Technology Reform Demonstration" enterprise of the State Council, and a national-level specialized and innovative "little giant" enterprise. The company focuses on the research and development and production of metal 3D printing equipment and alloy powder materials, masters core technologies such as high-performance alloy material design, spherical powder preparation, and high-precision selective laser melting equipment development, and provides users with one-stop service for metal 3D printing equipment, materials and processes. The products sell well in many countries and regions around the world, serving aviation, aerospace, medical care, automobiles, molds, consumer electronics, scientific research and other fields.

Recently, at the 12th Shanghai Injection Molding Forum, AVIC Metal Sales Director Chen Peng delivered a keynote speech on "Spherical Titanium Alloy Powder and Feeder for MIM". He introduced that with the continuous expansion of MIM application fields, especially 3C, sports outdoor and medical equipment and other product fields are favored for MIM titanium alloy technology, and the industry's demand for ultra-fine spherical titanium powder and feed products is unprecedented. Based on this, AVIC Metal has carried out a series of innovative research and launched high-quality MIM titanium powder, Feeding products and diversified solutions. MIM ultra-fine spherical titanium powder meets the industry's batch powder needs.

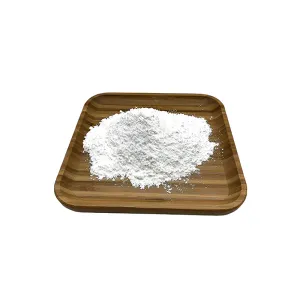

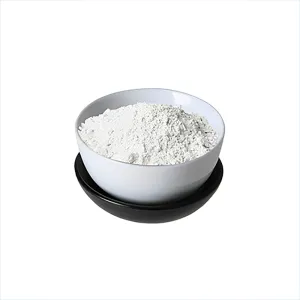

For the MIM industry, AVIC Mate has developed series of MIM special titanium powders such as TC4, TA15, TA0, and TC11, which are mainly based on particle size specifications such as 0 - 25μm, 0 - 40μm, and 0 - 53μm. The powder products have good sphericity, low oxygen and nitrogen content, good sintering activity, high density, and excellent comprehensive properties. They have been widely serving leading enterprises in the MIM industry and have been used in terminal scenarios such as 3C and medical devices.

In terms of titanium powder preparation, AVIC Mate innovatively adopts two major technical processes: "primary atomization method" and "regenerative refinement and crushing method", taking the lead in the industry in opening up a sustainable development path for the preparation of ultra-fine titanium powder; currently, the company has 600 tons The annual production capacity of ultra-fine titanium powder is open source for the industry's batch powder needs.