Recycling nylon is degraded and degraded, and chain extension modification should pay attention to these 4 key points!

May 29, 2024, 11:58 AM

TDD-global

6364

According to statistics, in 2021, the total consumption of nylon 6 chips in China will reach 4.127 million tons, and the consumption of nylon 66 will be about 640,000 tons.

According to statistics, in 2021, the total consumption of nylon 6 chips in China will reach 4.127 million tons, and the consumption of nylon 66 will be about 640,000 tons. Adding other nylon categories, the total nylon consumption is expected to be more than 5 million tons, and the global nylon consumption is about 5 million tons. 10 million tons. And this is only the data of last year. In the past few decades, the total consumption of nylon in China and the world has reached tens of millions or even hundreds of millions of tons.

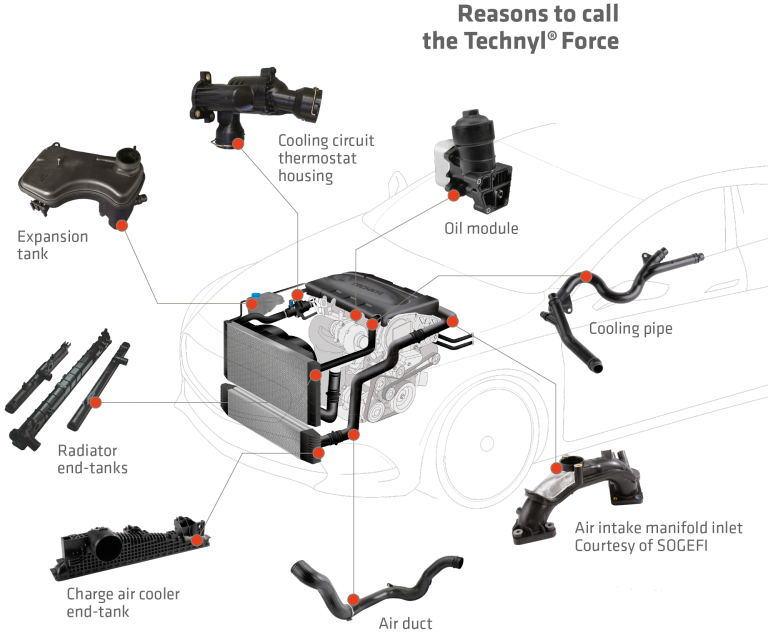

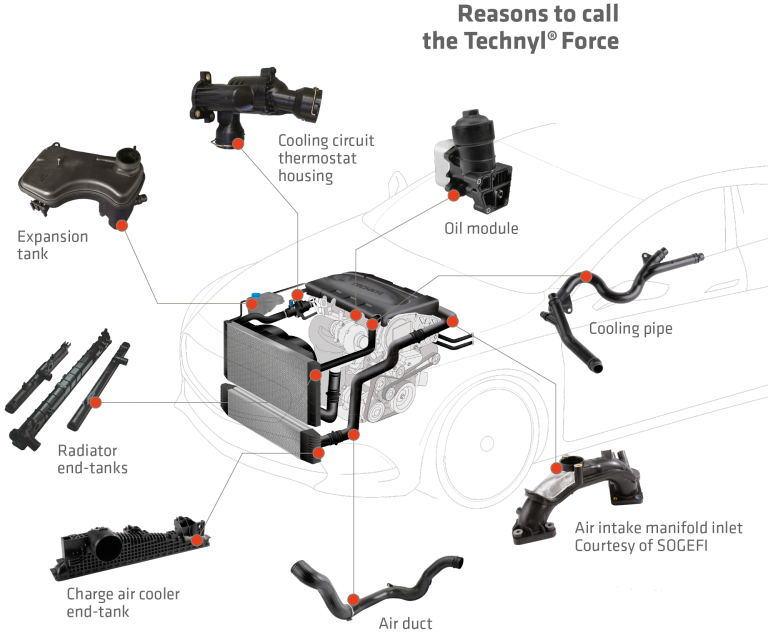

Nylon was developed in the 1930s. It was first used in the synthetic fiber industry, and then it was used as an engineering plastic due to its excellent physical and mechanical properties. It has developed rapidly and is currently widely used in the automotive industry, electrical industry, construction Materials, mechanical parts, medical equipment, and daily necessities.

Application of nylon in automobiles Source: DOMO Chemicals

Although nylon materials have good durability, most of the products made are durable goods. But over time, coupled with the huge volume, there will still be a large number of nylon products and materials that will become waste products, which will also cause harm to the environment.

With the implementation of environmental protection concepts such as carbon cycle, recycled nylon materials have been paid more and more attention by the upstream and downstream of the industry chain.

According to INVISTA, a certain recycled nylon 66 can achieve the same performance as new materials. In the production process, the production of new recycled nylon 66 reduces greenhouse gas emissions by 83% and energy consumption by 82% compared with virgin nylon 66. %, the water consumption is reduced by 57%. It can be seen that recycled nylon has huge practical and environmental value.

Nylon will degrade during processing, resulting in the loss of molecular weight, affecting the melt strength and processability of the polymer, and will also cause a certain degree of degradation due to environmental factors during use. Or recycled materials often cannot be used in applications with high performance requirements.

The nylon molecular chain is mainly composed of polyamide groups. After its degradation and chain scission, a large number of short-chain molecules containing terminal amino or terminal carboxyl active groups will be formed, which will cause the melt index of the material to increase and the heat resistance, strength, hydrolysis resistance and other properties to decline. If they are end-capped and chain-extended, their performance can be effectively improved.

Schematic diagram of nylon 66 structure

The chain extender increases the molecular weight of the polymer by coupling or branching the macromolecules through multifunctional compounds with good thermal stability. The chain extension reaction is usually completed by reactive extrusion technology, which has the advantages of simplicity, speed and safety, improves product performance, improves material quality, and thus improves the competitiveness of modified plastic products.

Nylon was developed in the 1930s. It was first used in the synthetic fiber industry, and then it was used as an engineering plastic due to its excellent physical and mechanical properties. It has developed rapidly and is currently widely used in the automotive industry, electrical industry, construction Materials, mechanical parts, medical equipment, and daily necessities.

Application of nylon in automobiles Source: DOMO Chemicals

Although nylon materials have good durability, most of the products made are durable goods. But over time, coupled with the huge volume, there will still be a large number of nylon products and materials that will become waste products, which will also cause harm to the environment.

With the implementation of environmental protection concepts such as carbon cycle, recycled nylon materials have been paid more and more attention by the upstream and downstream of the industry chain.

According to INVISTA, a certain recycled nylon 66 can achieve the same performance as new materials. In the production process, the production of new recycled nylon 66 reduces greenhouse gas emissions by 83% and energy consumption by 82% compared with virgin nylon 66. %, the water consumption is reduced by 57%. It can be seen that recycled nylon has huge practical and environmental value.

Nylon will degrade during processing, resulting in the loss of molecular weight, affecting the melt strength and processability of the polymer, and will also cause a certain degree of degradation due to environmental factors during use. Or recycled materials often cannot be used in applications with high performance requirements.

The nylon molecular chain is mainly composed of polyamide groups. After its degradation and chain scission, a large number of short-chain molecules containing terminal amino or terminal carboxyl active groups will be formed, which will cause the melt index of the material to increase and the heat resistance, strength, hydrolysis resistance and other properties to decline. If they are end-capped and chain-extended, their performance can be effectively improved.

Schematic diagram of nylon 66 structure

The chain extender increases the molecular weight of the polymer by coupling or branching the macromolecules through multifunctional compounds with good thermal stability. The chain extension reaction is usually completed by reactive extrusion technology, which has the advantages of simplicity, speed and safety, improves product performance, improves material quality, and thus improves the competitiveness of modified plastic products.

August 21, 2024, 2:42 PM

August 21, 2024, 2:28 PM

August 21, 2024, 2:20 PM

August 21, 2024, 3:01 PM