The son of crude oil, the great-grandfather of PTA - naphtha, how much do you know?

Among the huge families derived from the ancestors of crude oil, the most well-known ones may be gasoline, diesel, kerosene and other common energy products in our daily life, but in fact, this little-known child is also involved in all aspects of our livesââ It is naphtha.

The chemical fiber clothes, mineral water bottles, plastics and other chemical products we usually wear are basically from this little-known child. To a certain extent, aside from its father, crude oil, it is not wrong to say that it is the ancestor of most chemicals, so it is also called chemical light oil.

The name naphtha, at first glance, seems dull, clumsy, and a little cute. But people's names are not random. Regarding this name, there are currently two explanations: one is that because the boiling point of naphtha is low, it is usually extracted from the upper part of the distillation column in oil production, and the brain is also located in the upper part of the human body, hence the name naphtha; another explanation The English name of naphtha is naphtha. There is a syllable similar to the pronunciation of "brain". It is probably a method of transliteration when translating nouns from foreign documents.

1. Crude oil refining process in modern refineries

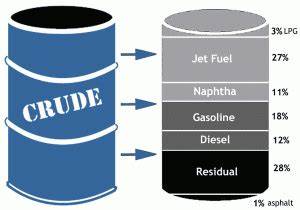

It's a long story to say how naphtha was derived from its crude father. In short, naphtha is an intermediate product of petroleum refining and a mixture of hydrocarbons. The refining process of modern crude oil is integrated, that is, through a large integrated device, through some physical processes and chemical reactions, one-time final production and separation of various main and by-products. In addition to our common products such as gasoline, diesel, kerosene, liquefied petroleum gas, fuel oil, asphalt, lubricating oil and coke, there is also a kind of intermediate product, naphtha, which most people have not heard of. Reprocessing yields benzene, mixed xylenes (aromatics) and ethylene propylene butadiene (olefins).

2. two major sources and classification of naphtha

I crude oil is produced by one-time processing and distillation: this part is based on the quality of the crude oil itself, the yield of crude oil with poor quality to naphtha is 2-3%, the medium yield is 20%-30%, and the special yield can reach 60% -70%. This part is called straight run naphtha.

II Naphtha produced by secondary processing: Naphtha is produced by hydrocracking, among which hydrogenated naphtha is the main one. This part has good properties and is low in sulfur and nitrogen.

In addition, traditionally, naphtha is also divided into light and heavy according to different distillation ranges and uses.

I light naphtha: the distillation range is 30-90 °C, the density is 0.69g/cm3, the sulfur content is 0.1%; the general light naphtha is used as a cracking raw material to make ethylene or gasoline blending components

II heavy naphtha: distillation range 80-180 â, density 0.72g/cm3, sulfur content 0.3%; general heavy naphtha is mainly used as a raw material for catalytic reforming.

However, naphtha is a mixture. In the actual process of purchasing naphtha raw materials, it is necessary to avoid simple division by "weight and weight", and pay more attention to what the main components of naphtha are. Different uses have different requirements for the hydrocarbon composition of naphtha, and the composition of the naphtha feedstock has a great influence on the required yield of finished products. Only in this way, can the limited naphtha resources be efficiently utilized to obtain maximum profits.

3.three major uses of naphtha

1. Catalytic reforming raw materials: the domestic demand is about 40%, and catalytic reforming produces aromatic hydrocarbon products such as benzene, toluene, and xylene; this type of products is mainly made into PX and then PTA.

2. Cracking raw materials: domestic demand is about 58%, cracking to produce olefins such as ethylene, propylene and butadiene. Among them, the demand for cracked ethylene accounts for the highest proportion, and the demand accounts for about 39% of the total demand for naphtha.

3. As solvent: used as raw material of petroleum resin and solvent of paint, pesticide emulsifier, silver powder rolling paste, etc.

4. Naphtha and PTA

Naphtha is produced from petroleum through a certain process, and MX (mixed xylene) is extracted from the naphtha, and then PX (para-xylene) is extracted. PTA uses PX (65%-67% formula) as raw material, acetic acid as solvent, and is oxidized by air under the action of catalyst (oxygen accounts for 35%-33%) to generate crude terephthalic acid. Then, the crude terephthalic acid is subjected to hydrorefining to remove impurities, and then purified terephthalic acid is obtained through crystallization, separation, and drying, that is, the finished product of PTA.