It is now in March, the most lively season of the year in the textile market.However, for the textile industry, I feel a silk of cool, visiting the textile industry gathering places, the previous heavy traffic scene disappeared, and even some markets do not open due to the epidemic.

The textile market in March this year, under the pressure of the international situation and the epidemic, is not as busy as in previous years.In this so-called textile season, this year's textile owners, even no chance to fight a price war.So many textile people think that the subsequent market is not as optimistic.

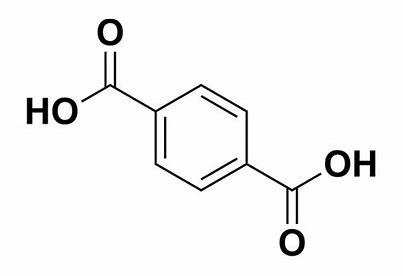

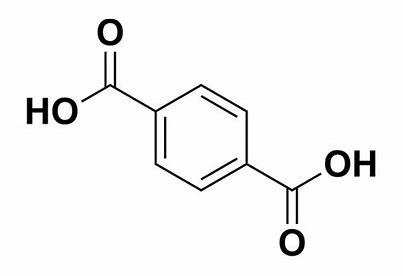

1. PTA: Some factories have successively released maintenance and negative reduction messages

Since the end of February, due to the continuous low processing fee, some PTA factories have released maintenance, reduce the negative news.Currently Yisheng Ningbo 2 million tons restart time to delay, Yisheng new material devices to maintain a set of half operation, Fuhai 4.5 million tons to 8 into early march, yizheng chemical fiber 350000 tons of plant stopped in early march, hengli petrochemical line 42.5 million tons on March 10; maintenance of Yangtze petrochemical 650000 tons, Zhuhai English 1.25 million tons in late March, hengli petrochemical line 1, Jiaxing petrochemical plant maintenance in April.

At present, the maintenance of PTA devices is gradually clear, some devices in Yisheng have begun to overhaul, Hengli also has maintenance plans in March and April, Fuhaichuang also fell negative in early March, the supply side has begun to shrink, and the market gradually began to go to storage.PTA factory overhaul more, capacity utilization has been at the low point of the year, but the supply side compression did not change the disk for two weeks of consecutive decline.On the one hand, affected by the cost collapse, on the other hand, the demand side support is insufficient.As PX squat is greater than PTA, its processing cost has recovered from the previous month, but did not get rid of the loss dilemma.Combined with the domestic multi-point epidemic to curb demand and shipment, downstream buying sentiment is not good.

2, This fall, fell out of the polyester profits, the mainstream polyester factories or collective production reduction intention

Similarly, with the volatile decline of crude oil, the upstream PTA cost of polyester fell, yielding some of the profit to polyester. However, due to the no increase in terminal orders, polyester production and sales are flat, and polyester factories are high construction, so there is subsequent negative pressure.Recently, financial Union reporter learned that the recent mainstream polyester factory or collective production intention, Hengyi petrochemical, Sanfang lane, Rongsheng petrochemical and other polyester factories in mid-late March maintenance plan, but according to the data, the current polyester start load is about 93-94%, polyester inventory is still high.

3. Weaving clothing: The decline will expand significantly in the end of March and early April

Recently, the epidemic has been spread in China, and all regions have increased prevention and control measures and adhered to the "dynamic zero", which has affected the production, transportation and sales of some enterprises and the business of some light textile market traders.Following the suspension of Dongguan Dalang Wool Trading Center, Hangzhou Sijiqing Clothing Block and other cities, Huzhou Zhili Children's Wear City and Zhili International Light Textile City have also announced to be closed indefinitely.

In addition, it is understood that the weaving factories in Jiangsu and Zhejiang regions have been reducing production and negative burden in the last one or two weeks. By March 16, the comprehensive starting load of looms is less than 70%, and it may fall to less than 60% by Tomb-sweeping Festival."Business used to be good in March and April, but now it has to fall, indicating that orders are very poor."Industry experts mentioned that the opening rate of weaving factories is now slightly down, to the end of March and early April, the decline will expand significantly, or reduce by about 10%, in the case of frequent fluctuations in the raw material market, the downstream will only continue to wait and see in the short term.

Not only the trend of international oil prices, but also the risk of the epidemic, high oil prices and high transportation costs, all have had a significant impact on serving textile enterprises. At present, most enterprises maintain basic orders, or even start the production reduction mode.Polester production is expected to be reduced next week, such a "production cut tide", as a vicious cycle, will undoubtedly hurt all links of the textile industry chain, so can the textile industry chain in April usher in a new turning point?At present, we can only continue to pay attention to the changes on the demand side and the cost side.